多仓库路线配置工具

Dmmsys 124358678@qq.comStock Route Configuration Tool

Odoo's inventory system is the core business underlying function of the entire ERP system. Different from traditional ERP systems' inventory, Odoo adopts inventory double entry bookkeeping,

Every inventory change (such as sales, purchases, transfers) will simultaneously record a decrease in the source storage location and an increase in the target storage location.

The Odoo inventory movement mechanism based on double entry bookkeeping realizes the entire production organization process, from the initial raw material procurement location to the final finished product delivery location for each level of material,

Forming a complete replenishment chain for material flow, Odoo uses material routes to match the flow process of each level of materials, thereby achieving a business process from the perspective of materials for the entire company.

However, the Odoo native inventory route has the following shortcomings and cannot fully meet the needs of the manufacturing industry for rapid configuration of business processes:

1. A warehouse can only execute one type of route, single step, two-step, or three-step cannot coexist.

2. When a material exists at different levels of BOM and is needed in multiple warehouses, it cannot be received and issued according to the actual business needs.

3. Unable to quickly configure the entire company's business processes, too many routes require manual creation.

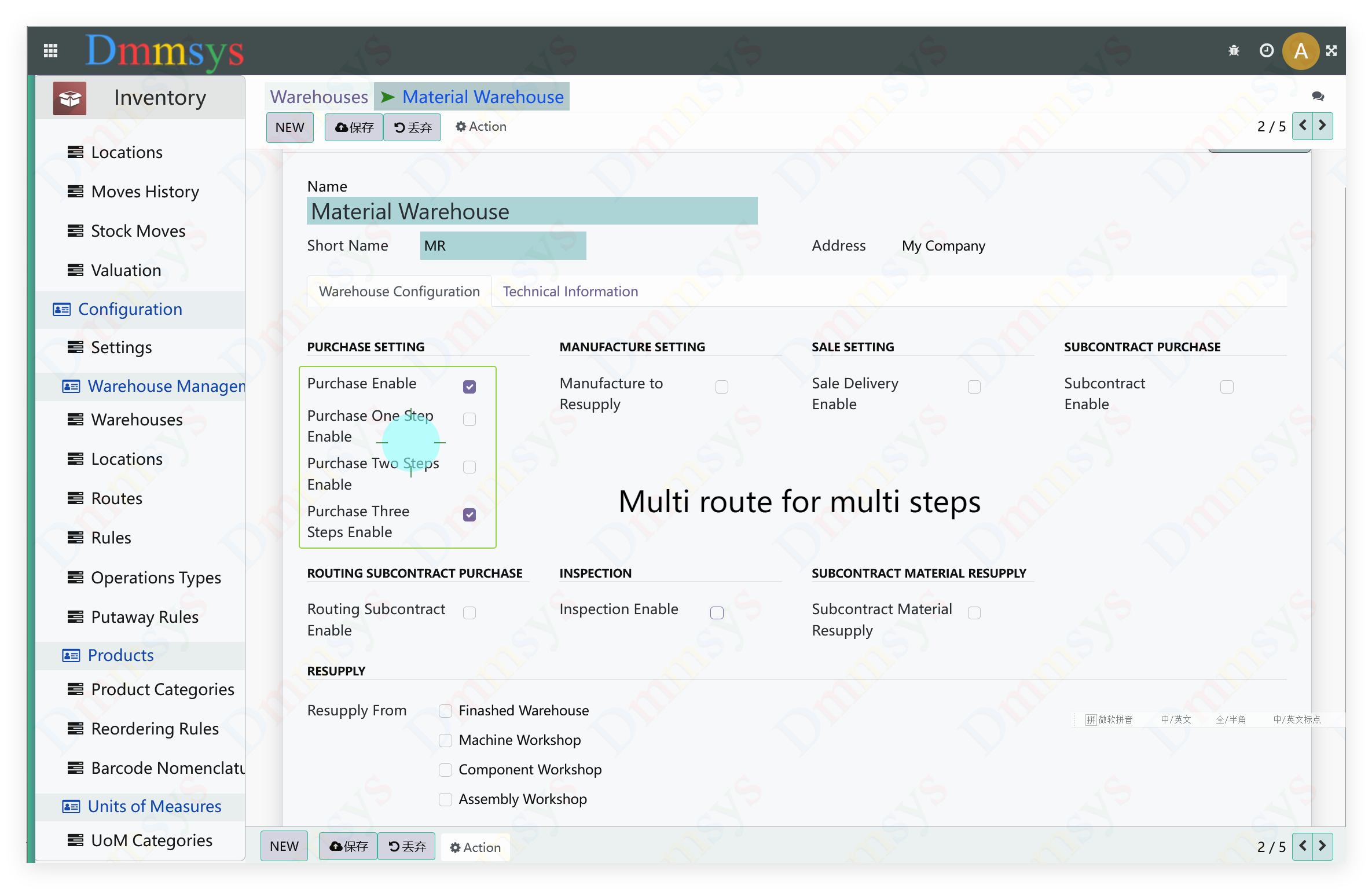

To address the issues and shortcomings of the native features mentioned above,

we have developed a rapid process configuration tool.

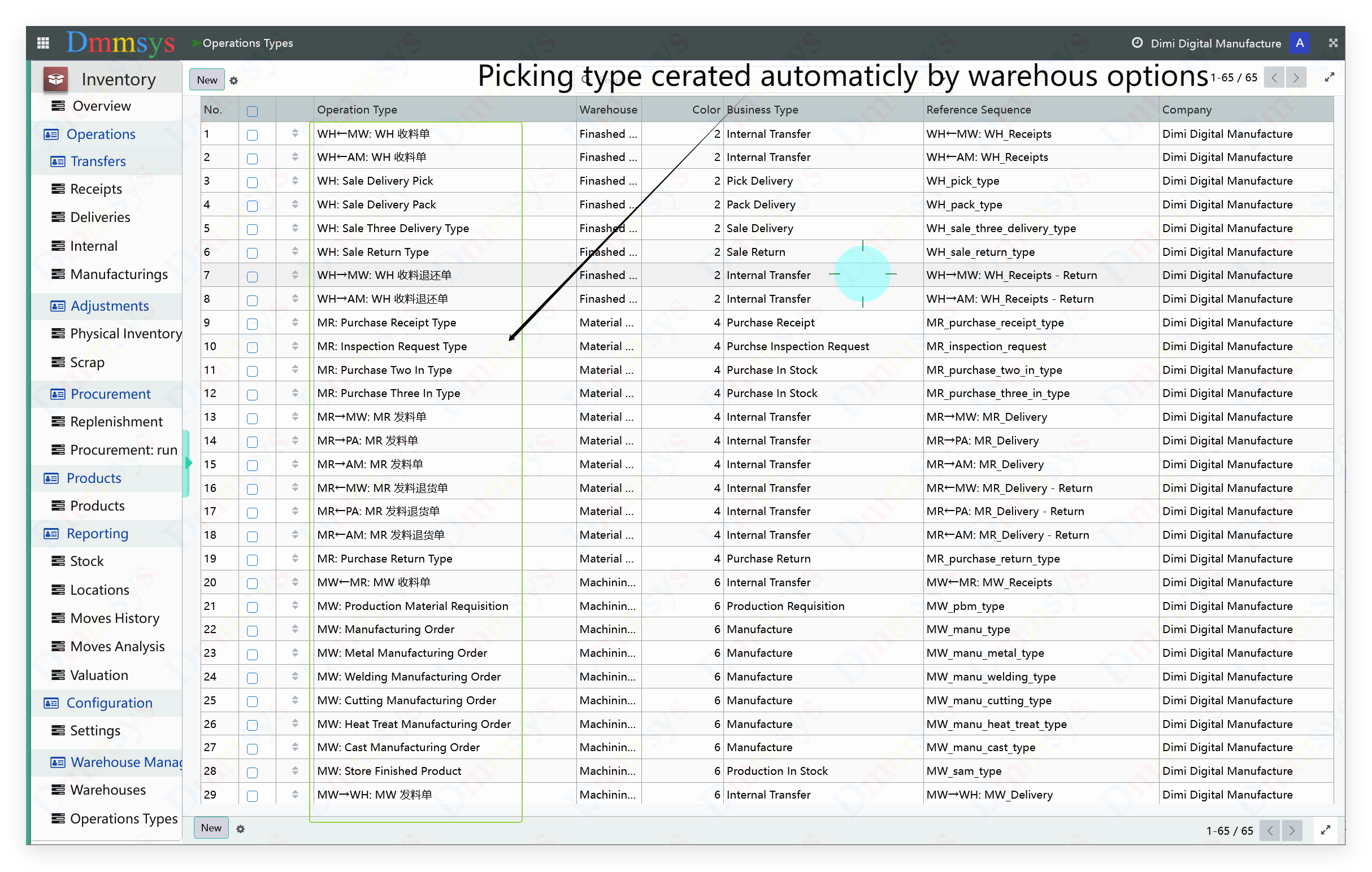

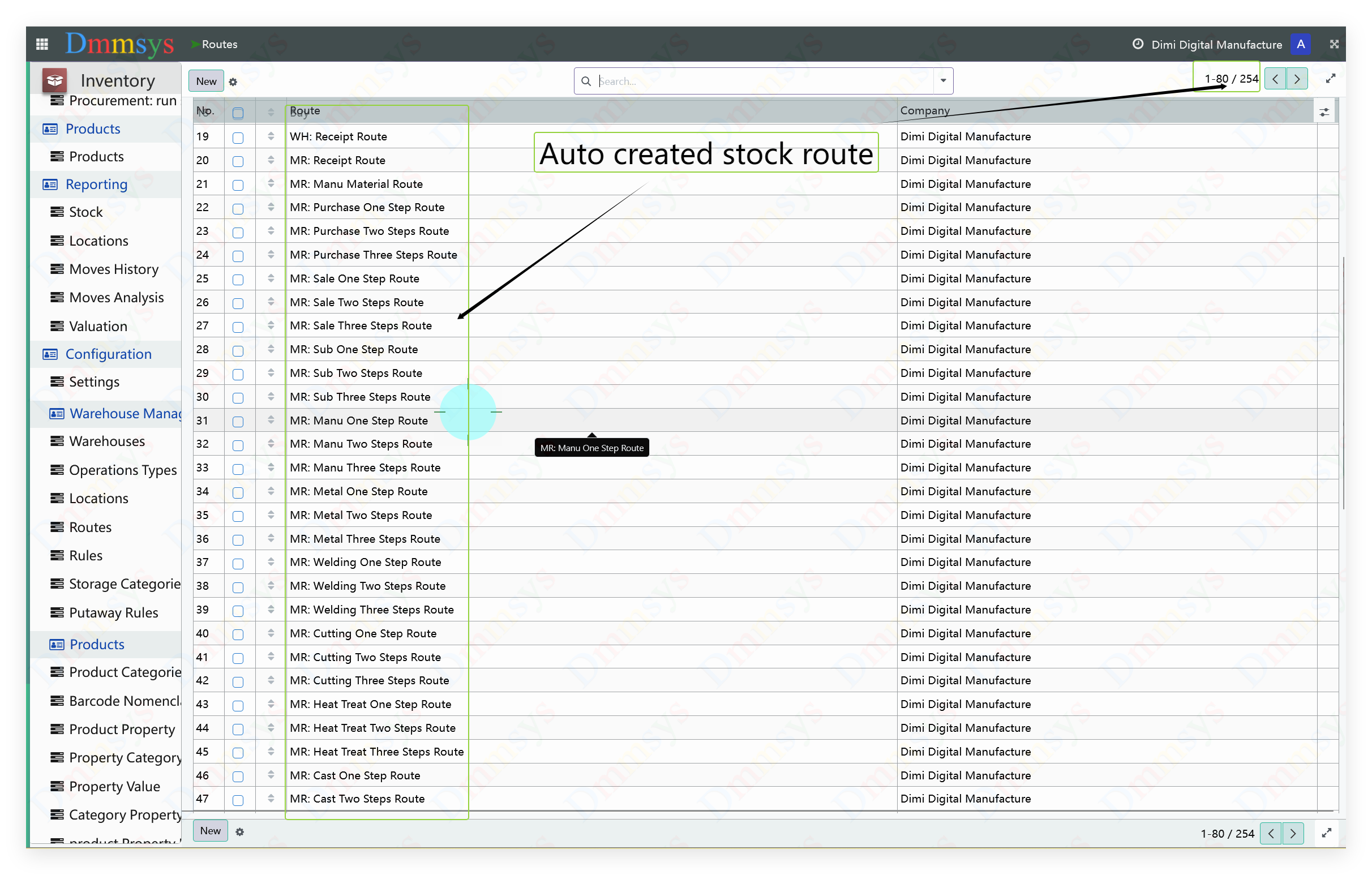

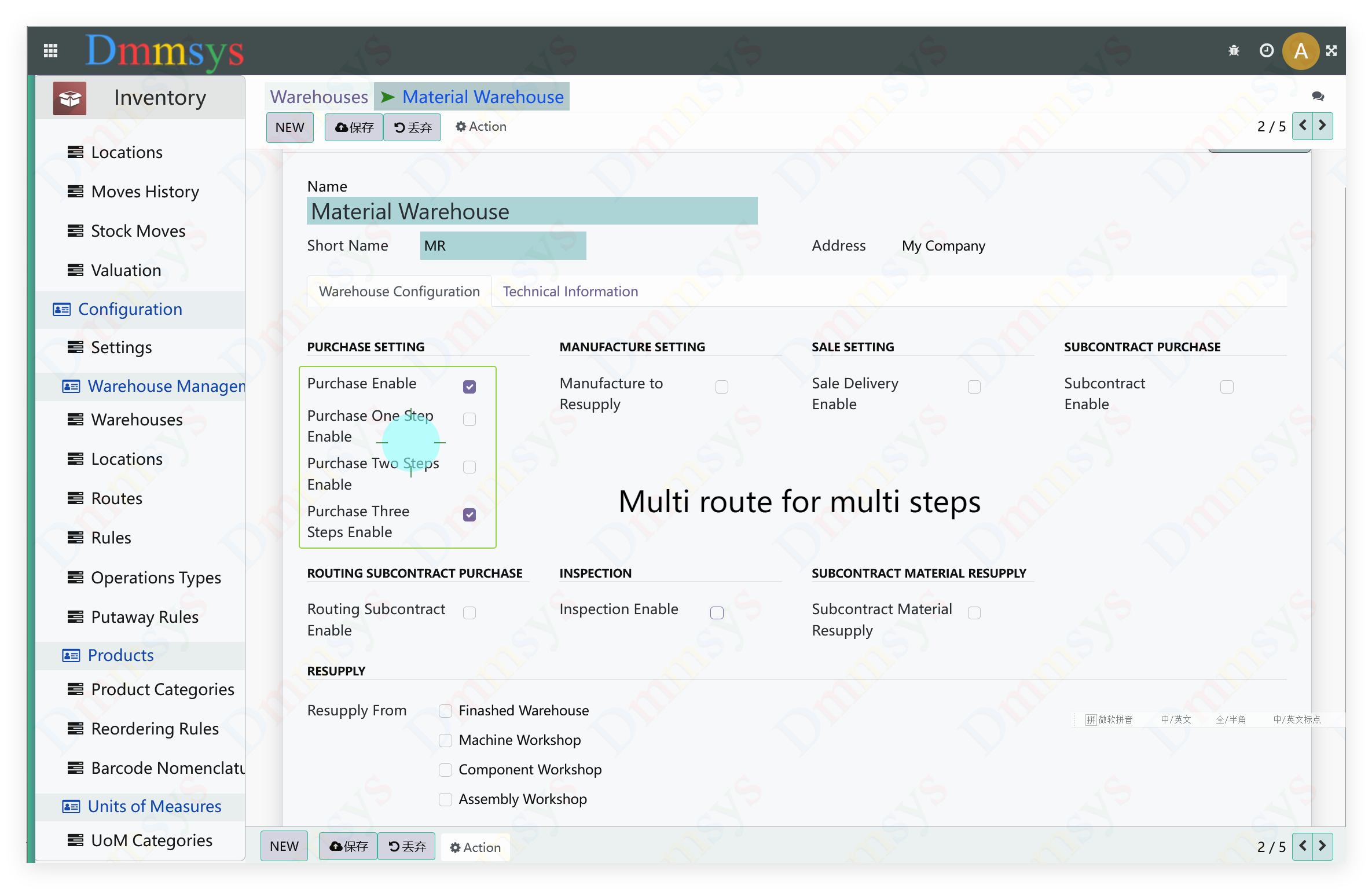

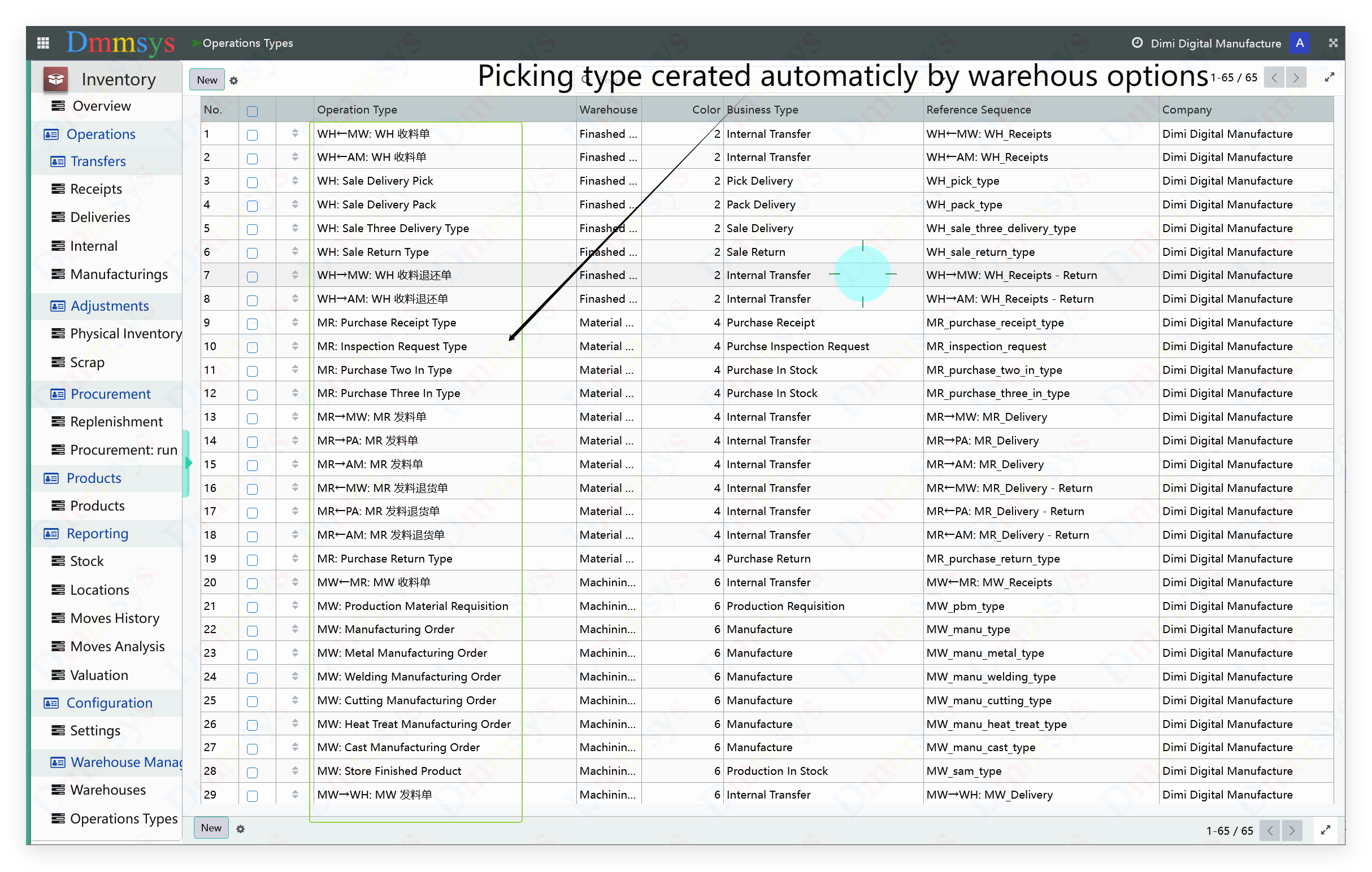

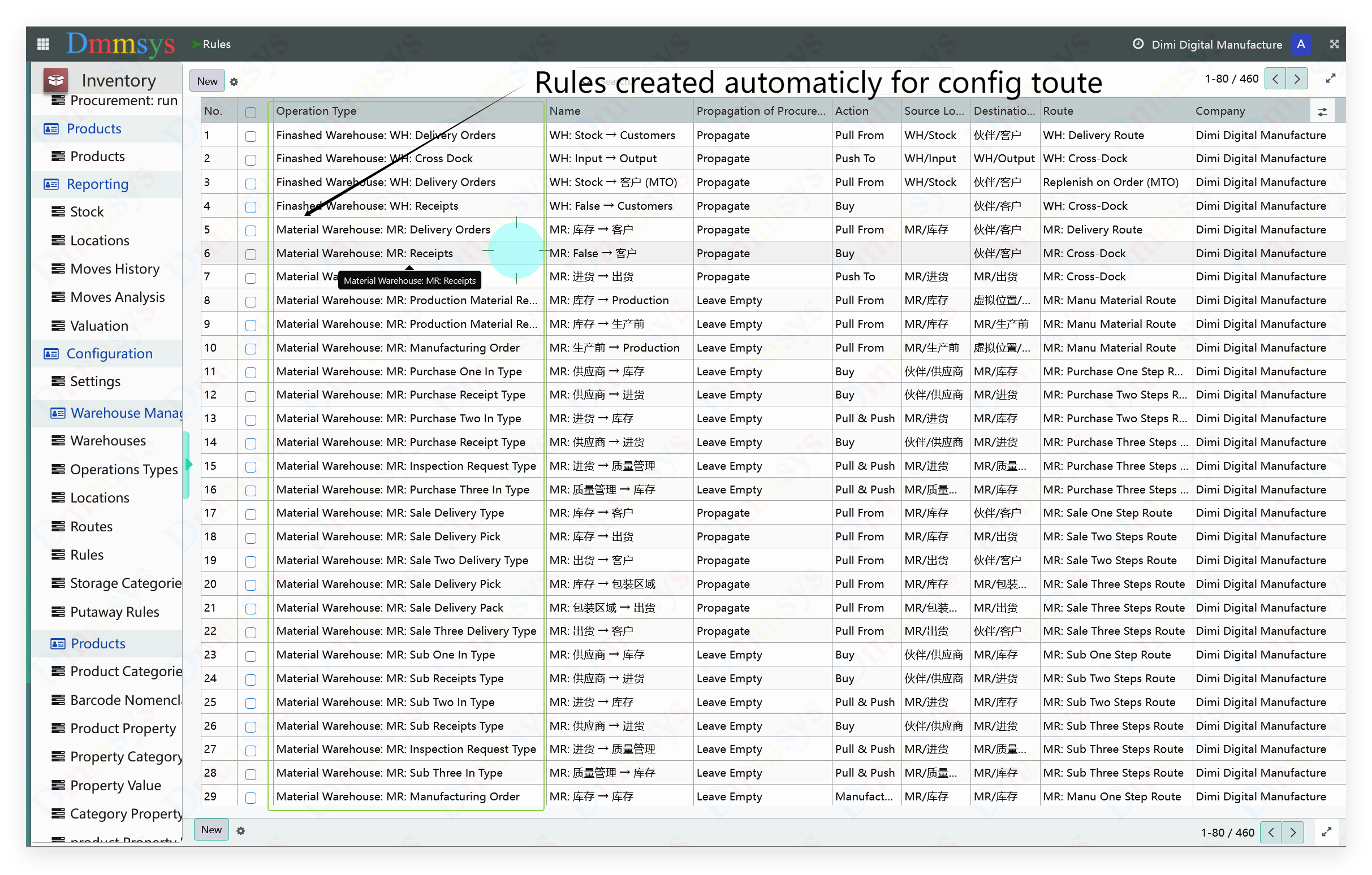

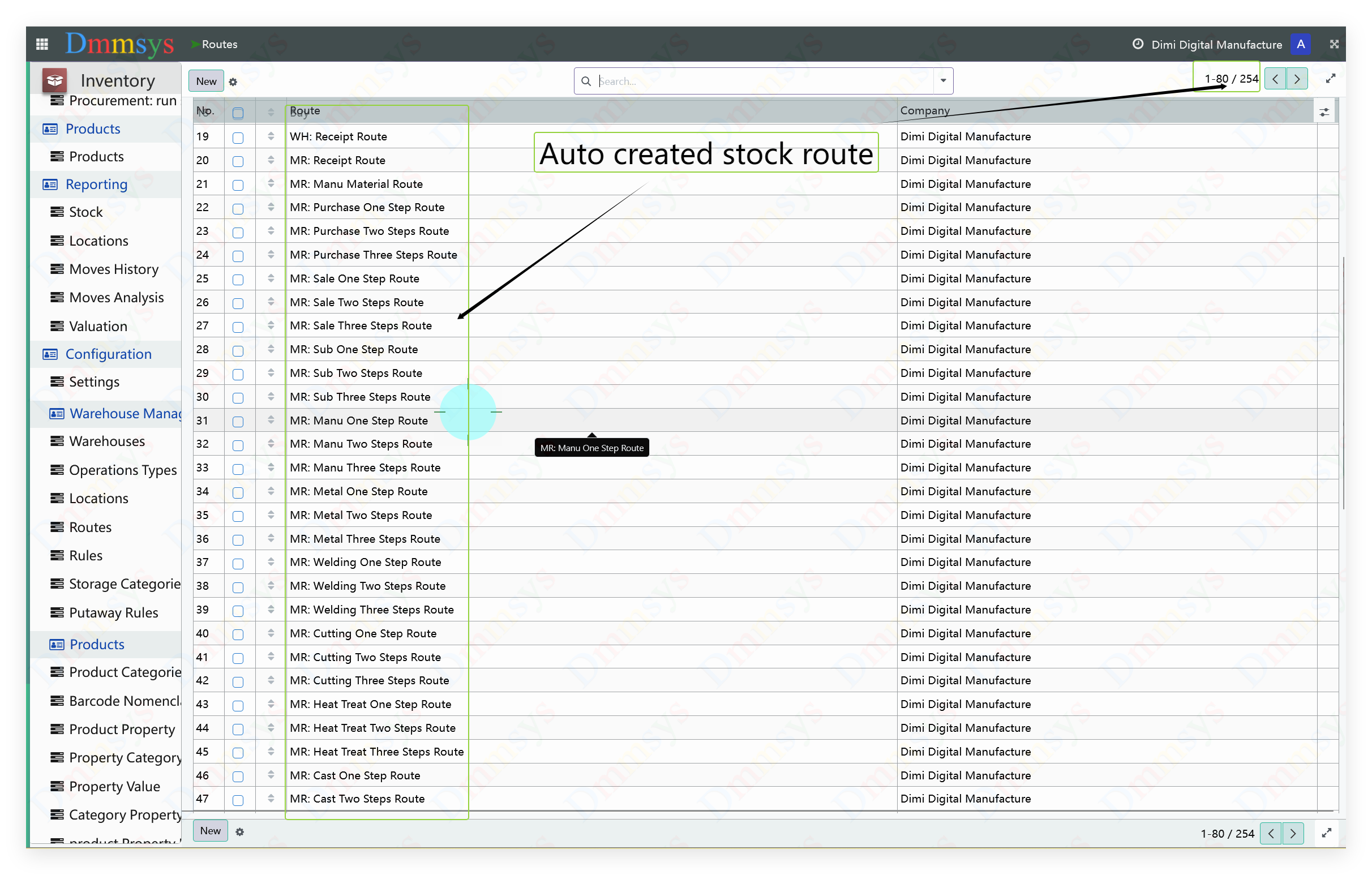

Just check the option for multi-step routes on the warehouse to quickly create

all the picking types and stock routes required for complex business scenarios.

业务流程配置工具

Odoo的库存系统是整个ERP系统最核心的业务底层功能,区别于传统ERP系统的库存,Odoo采用库存复式记账,

每一笔库存变动(如销售、采购、调拨)都会同时记录源库位的减少和目标库位的增加。

基于复式记账的Odoo库存移动机制,实现了整个生产组织过程中,每一级物料,从最初的原料采购位置到最终成品交货的位置,

构成了一个完整的物料流动的补货链路,所以Odoo使用物料的路线,来匹配每一级物料的流动过程,从而实现整个公司的物料角度的业务流程。

但是Odoo原生库存路线存在下面的不足,不能完全满足制造行业快速配置业务流程的需求:

1、一个仓库只能执行一种步数的路线,单步,两步,或者三步不能共存。

2、当一个物料存在于bom不同层级,在多个仓库都需要时,不能按照业务实际的需求收料和发料。

3、不能快速实现整个公司业务流程的配置,太多的路线需要手工去创建。

为解决上述原生功能的问题及不足,我们开发了快速流程配置工具,只需要在仓库上勾选多步路线的选项,

就可以快速创建复杂业务场景所需的全部的作业类型和路线。

Key Feature

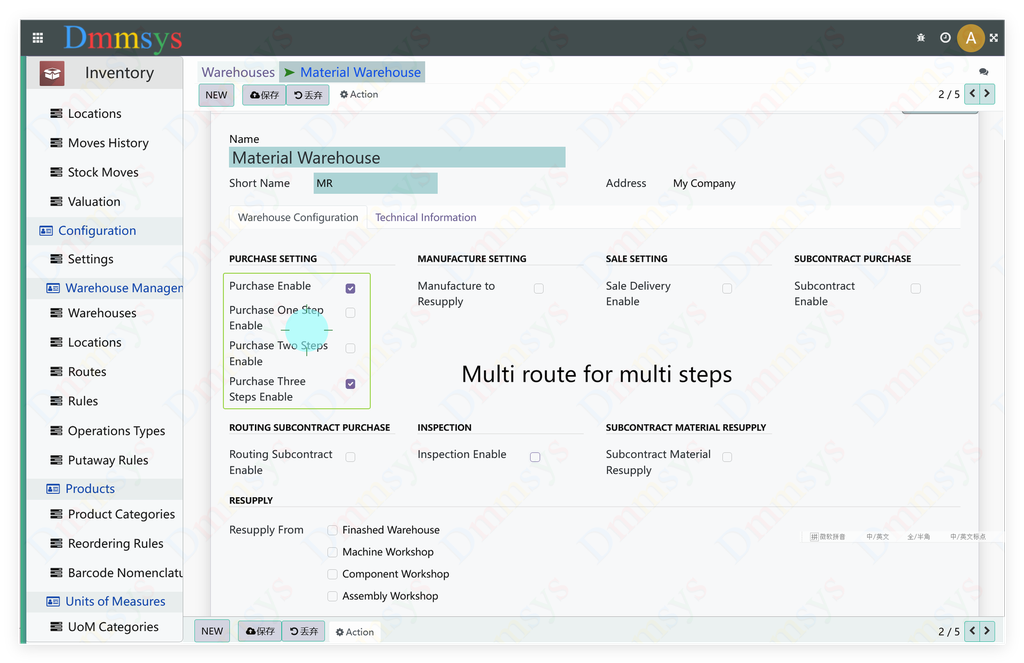

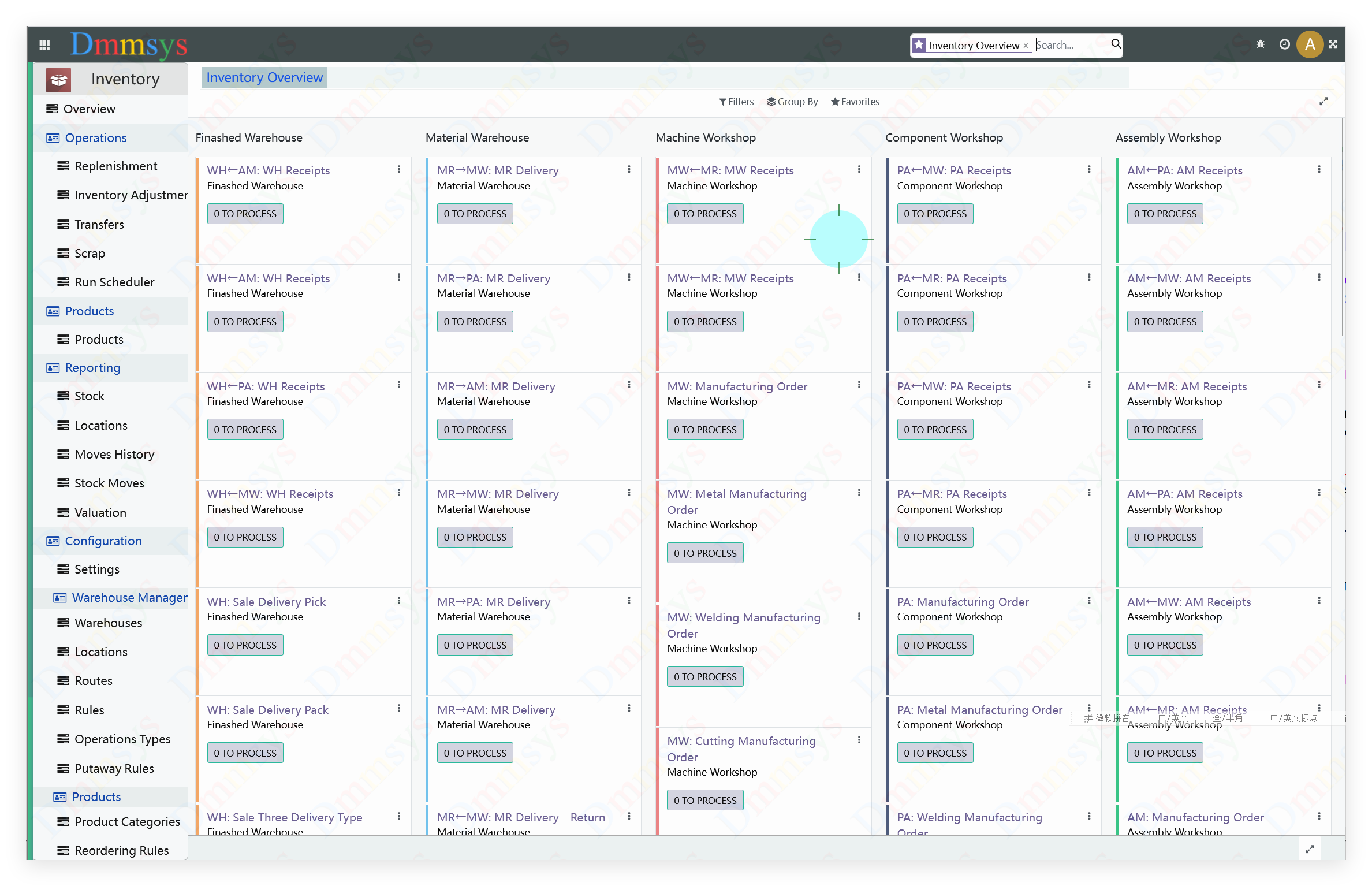

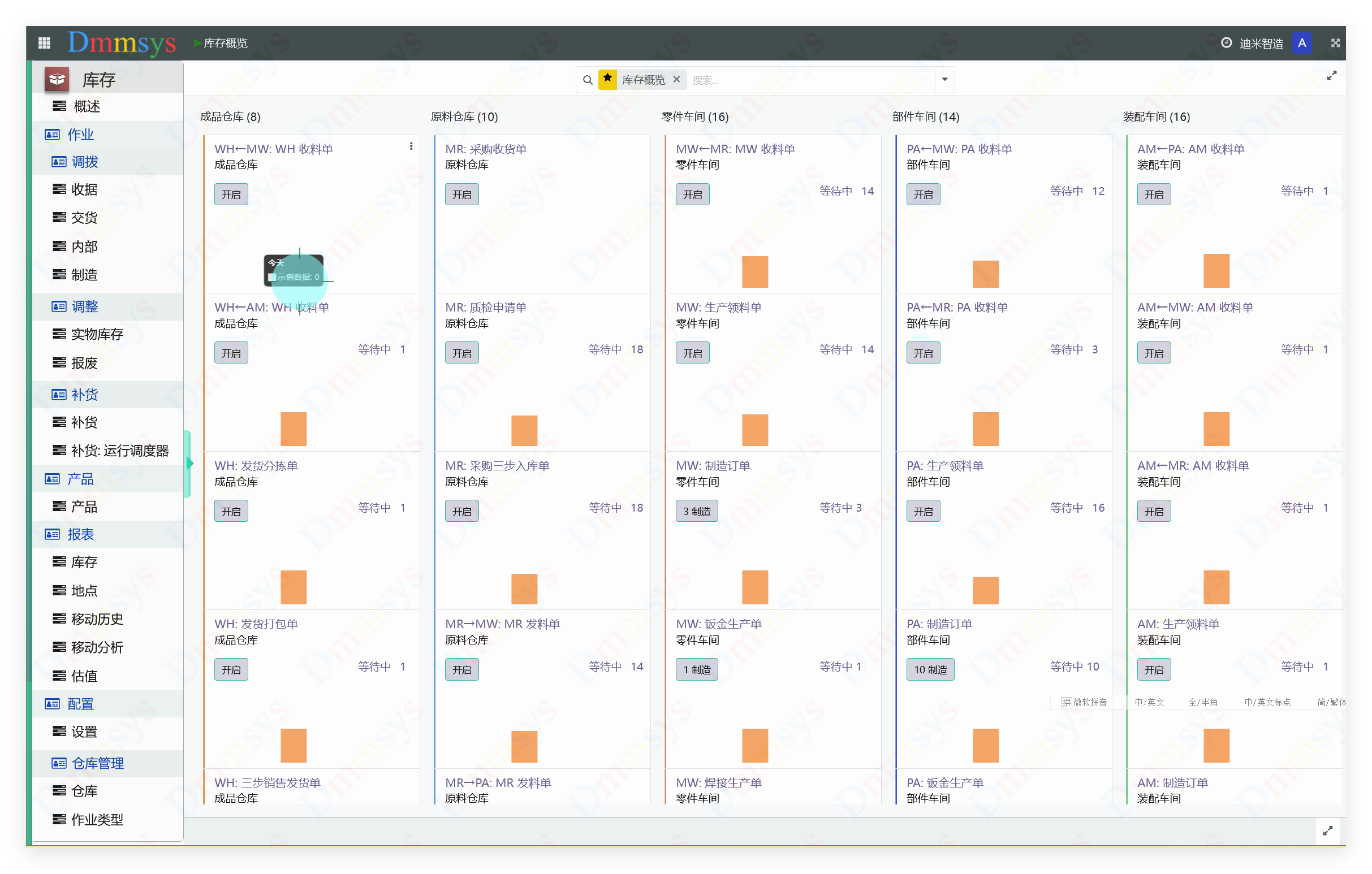

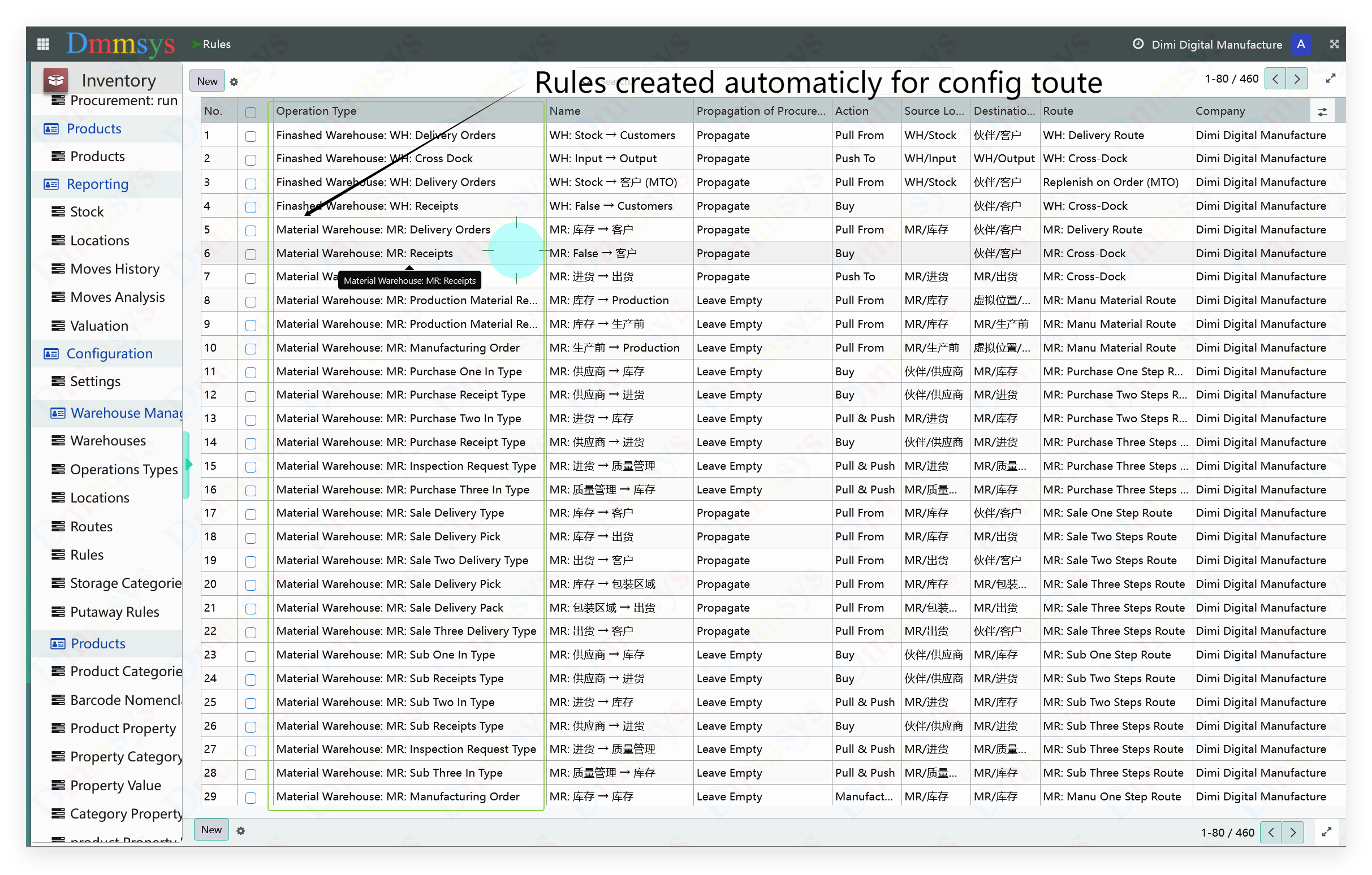

A powerful route configuration tool developed based on native inventory route expansion.By selecting the option button on the warehouse, it automatically creates all material routes that conform to the actual business process

Core route functions

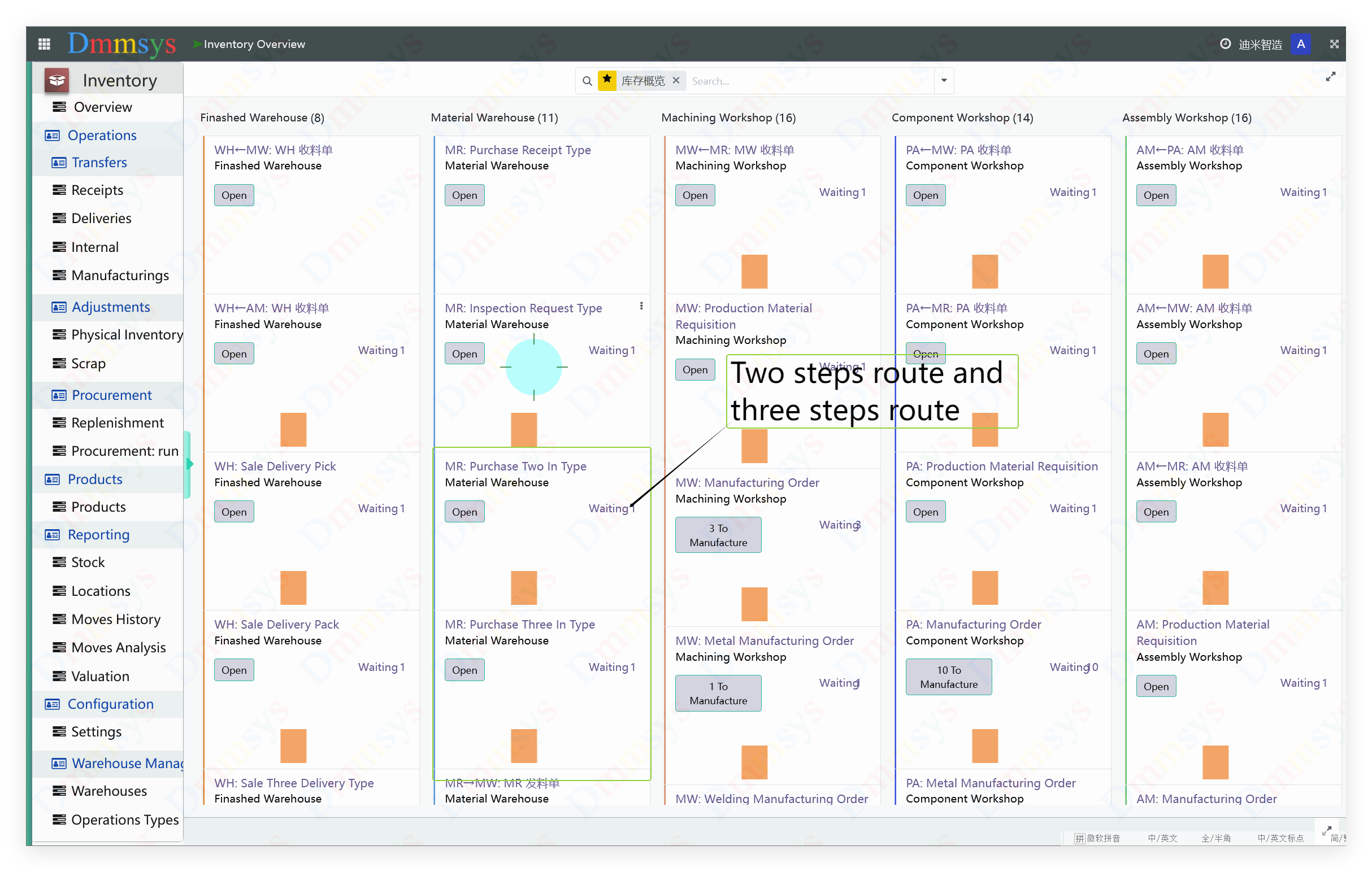

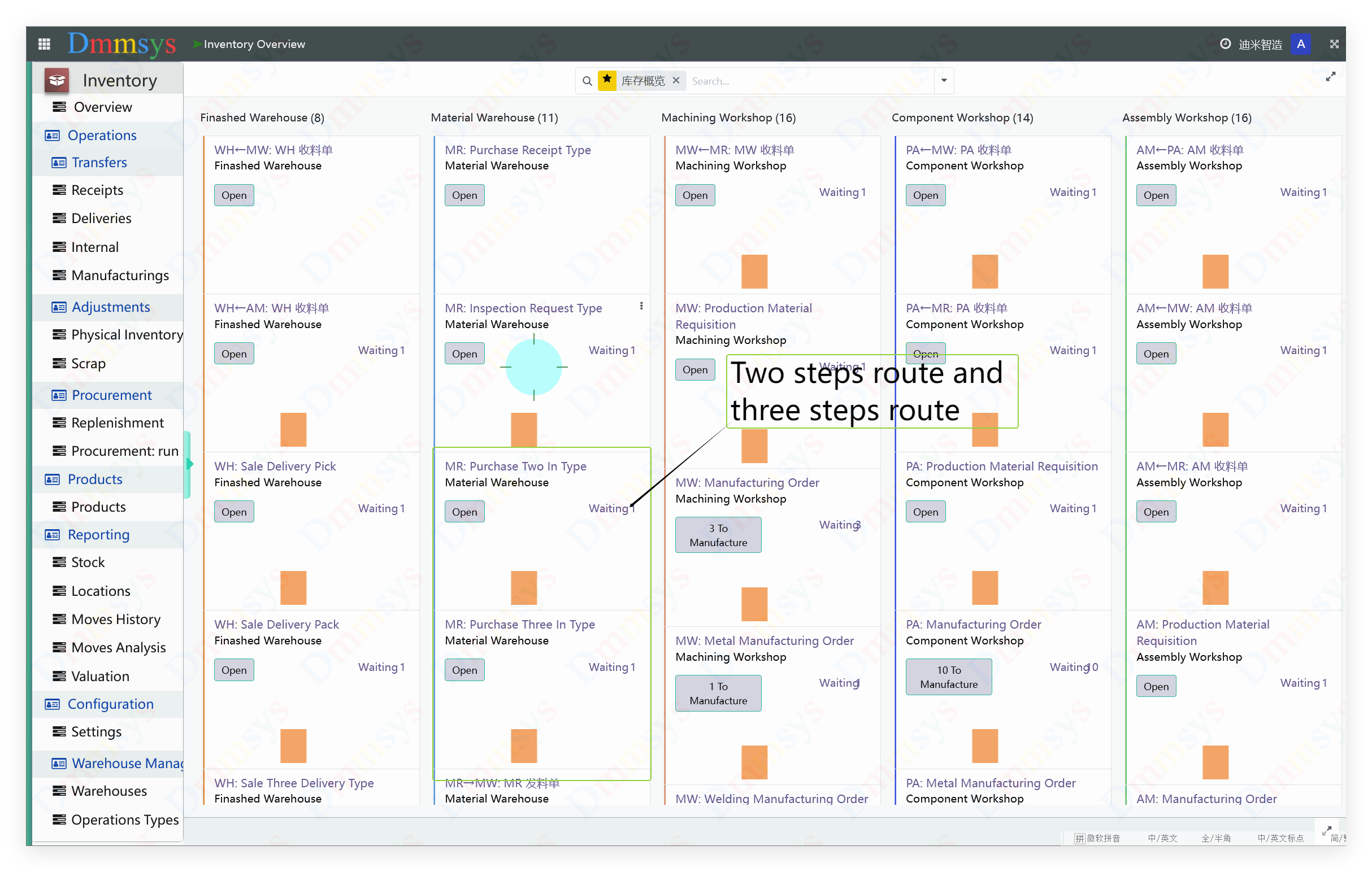

The inventory route configuration tool solves the problems and shortcomings of the original inventory route..Coexistence of multi-step routes

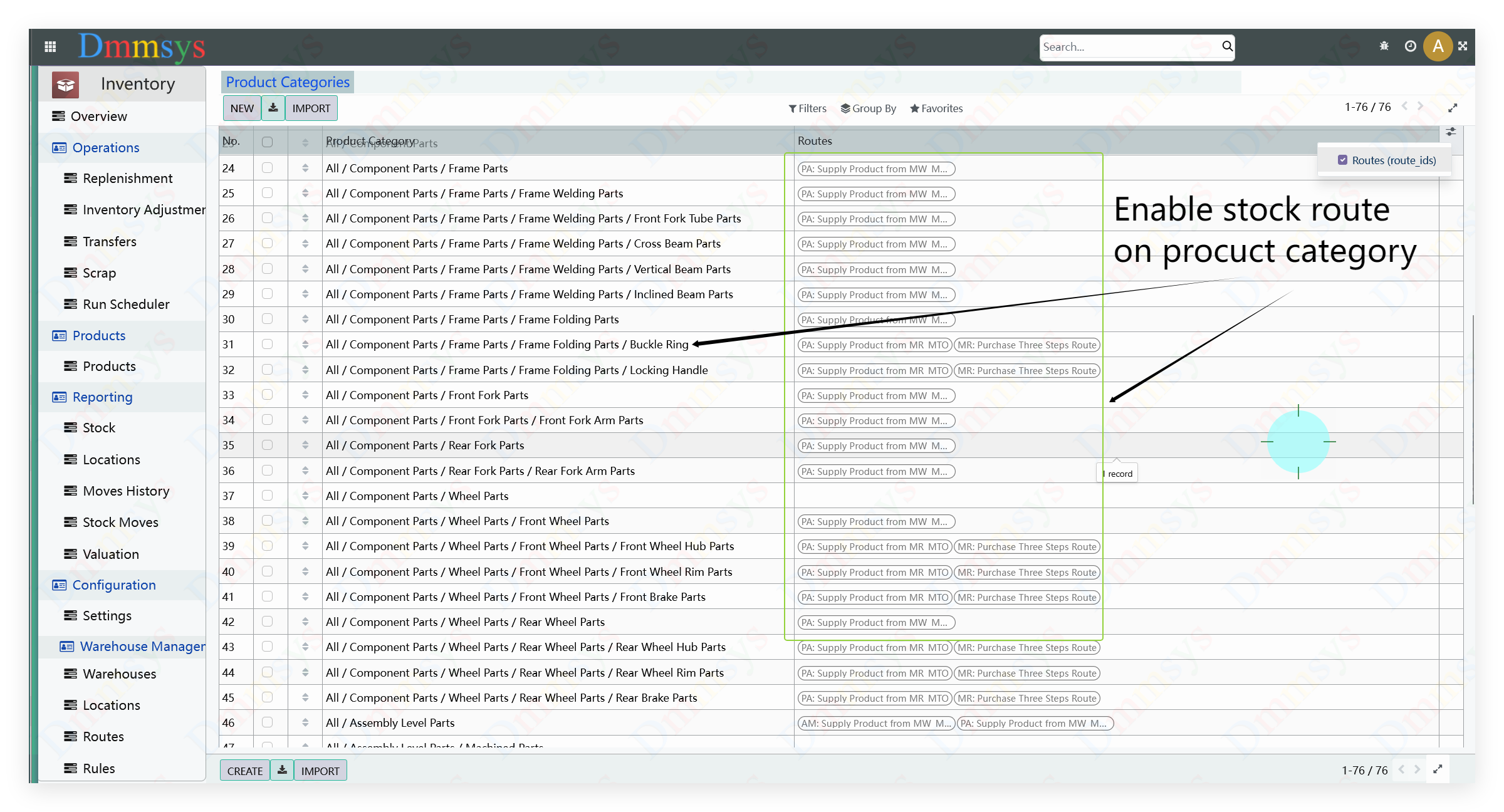

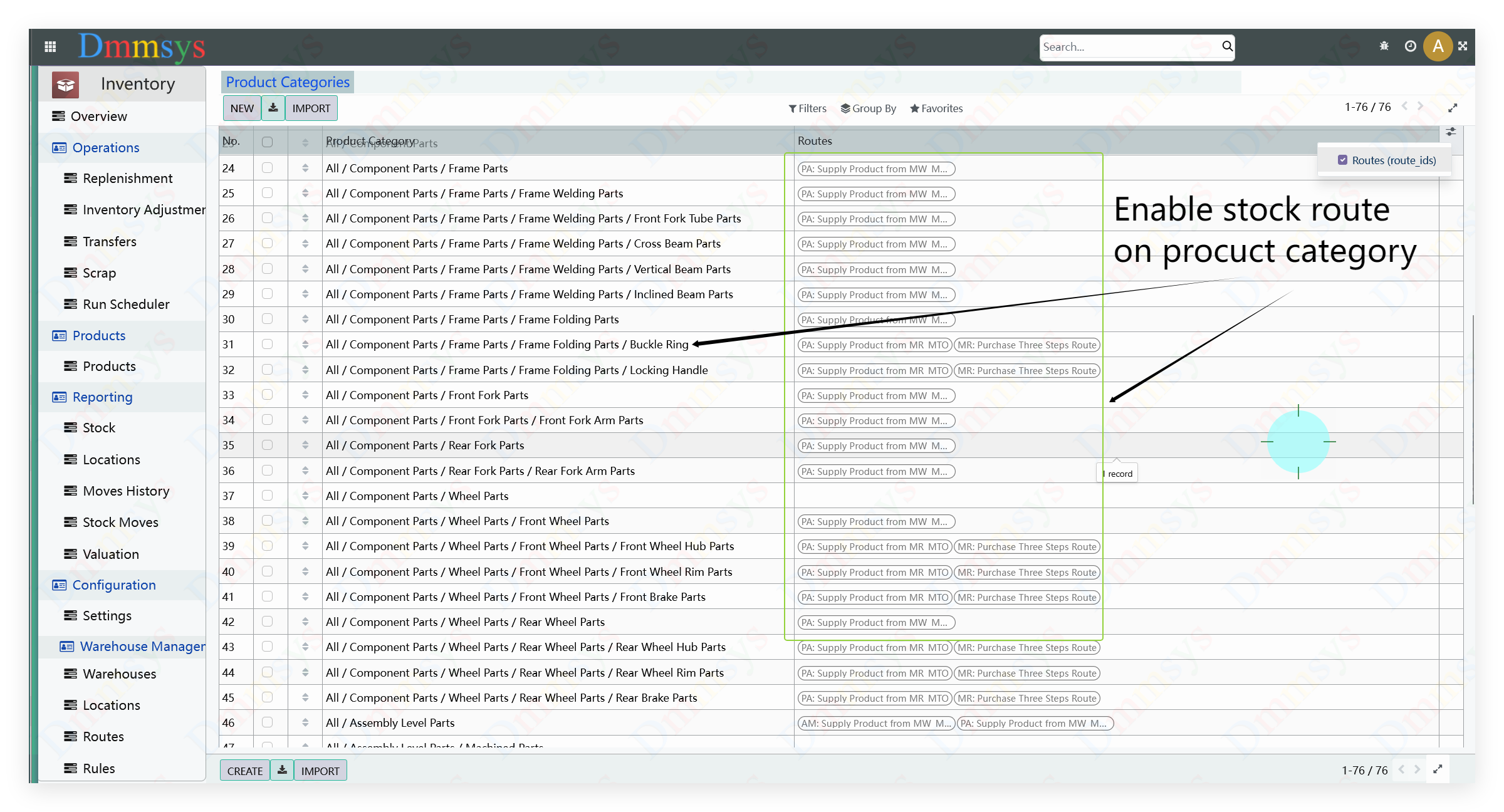

By changing the original single selection mechanism of multi-step routes to a double selection mechanism, it is possible to configure different step routes for materials of different categories simultaneously in the same warehouse.

For example, the raw material warehouse implements a two-step inspection free storage route for materials that do not require quality control, and a three-step storage route for materials that require quality control. The manufacturing workshop can configure a route for material requisition and production for the initial starting section of the workshop, and a single step production route for production orders in the intermediate section, Configure a post production quality inspection route for the production order of the final warehouse section.

Unified Access Control

By developing precise cross warehouse routes and perfectly matching the same material that needs to be replenished in multiple warehouses at different BOM nodes in actual business, replenishment can be carried out according to the correct process and quantity.

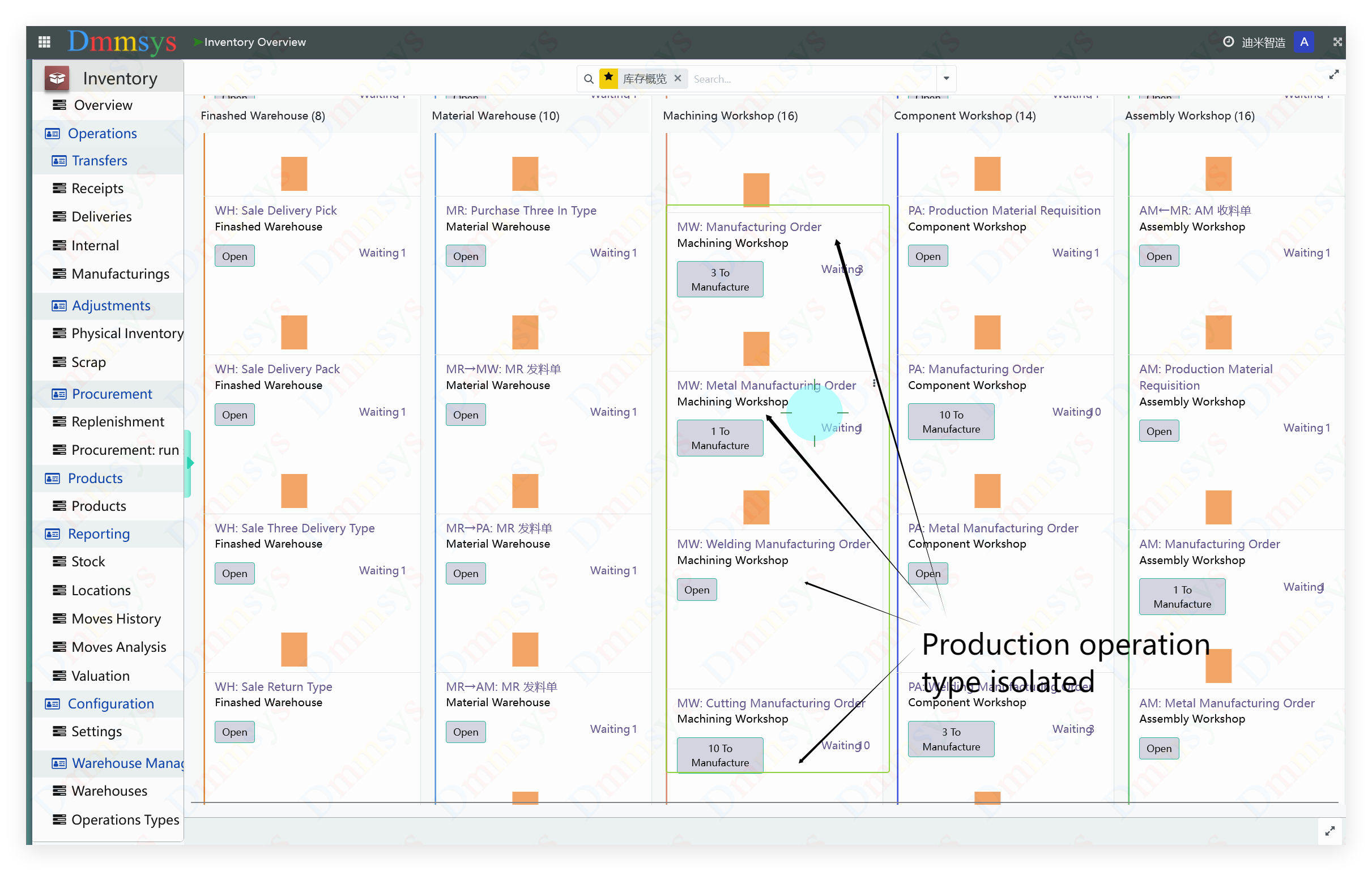

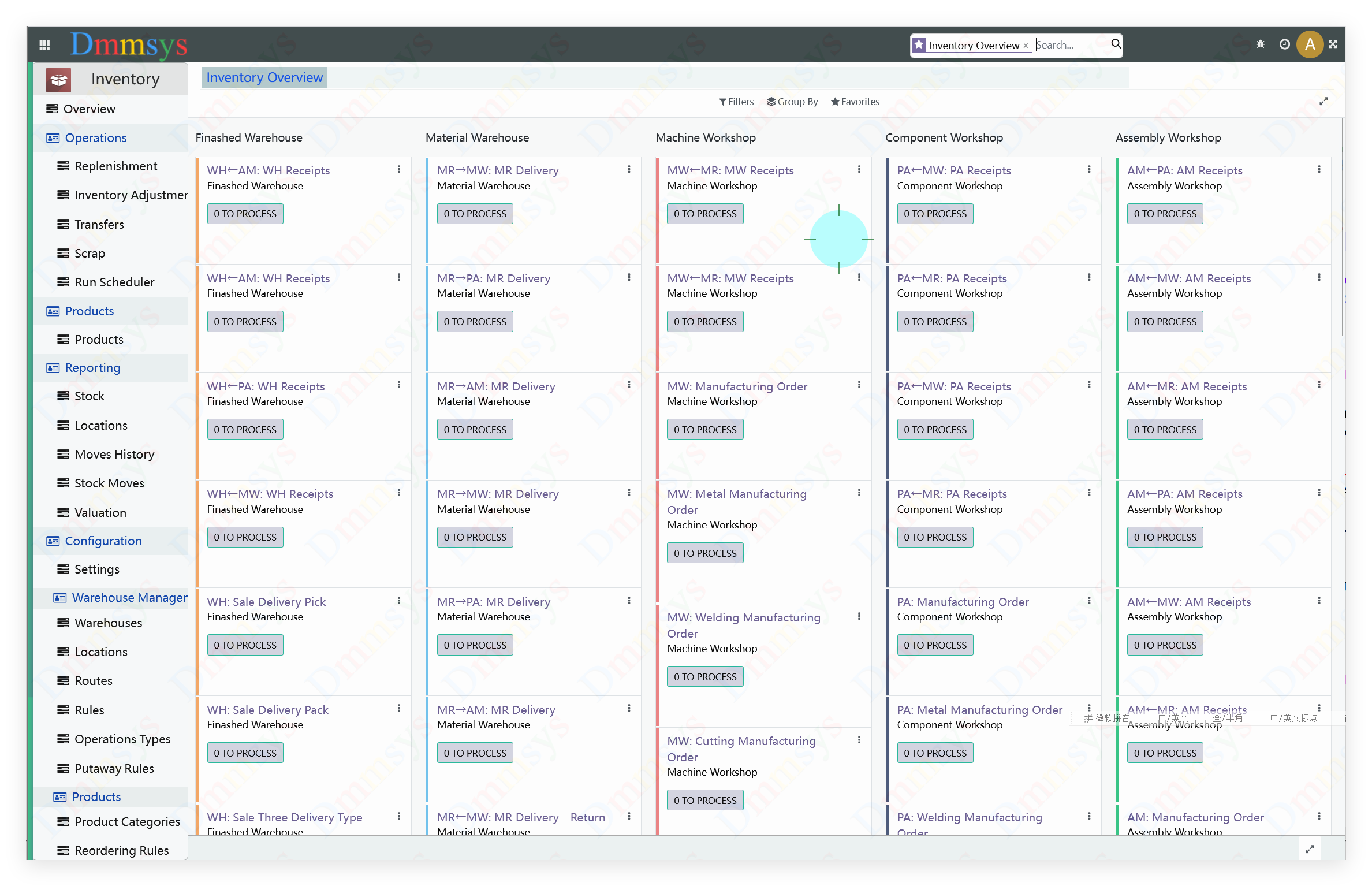

Picking type extension

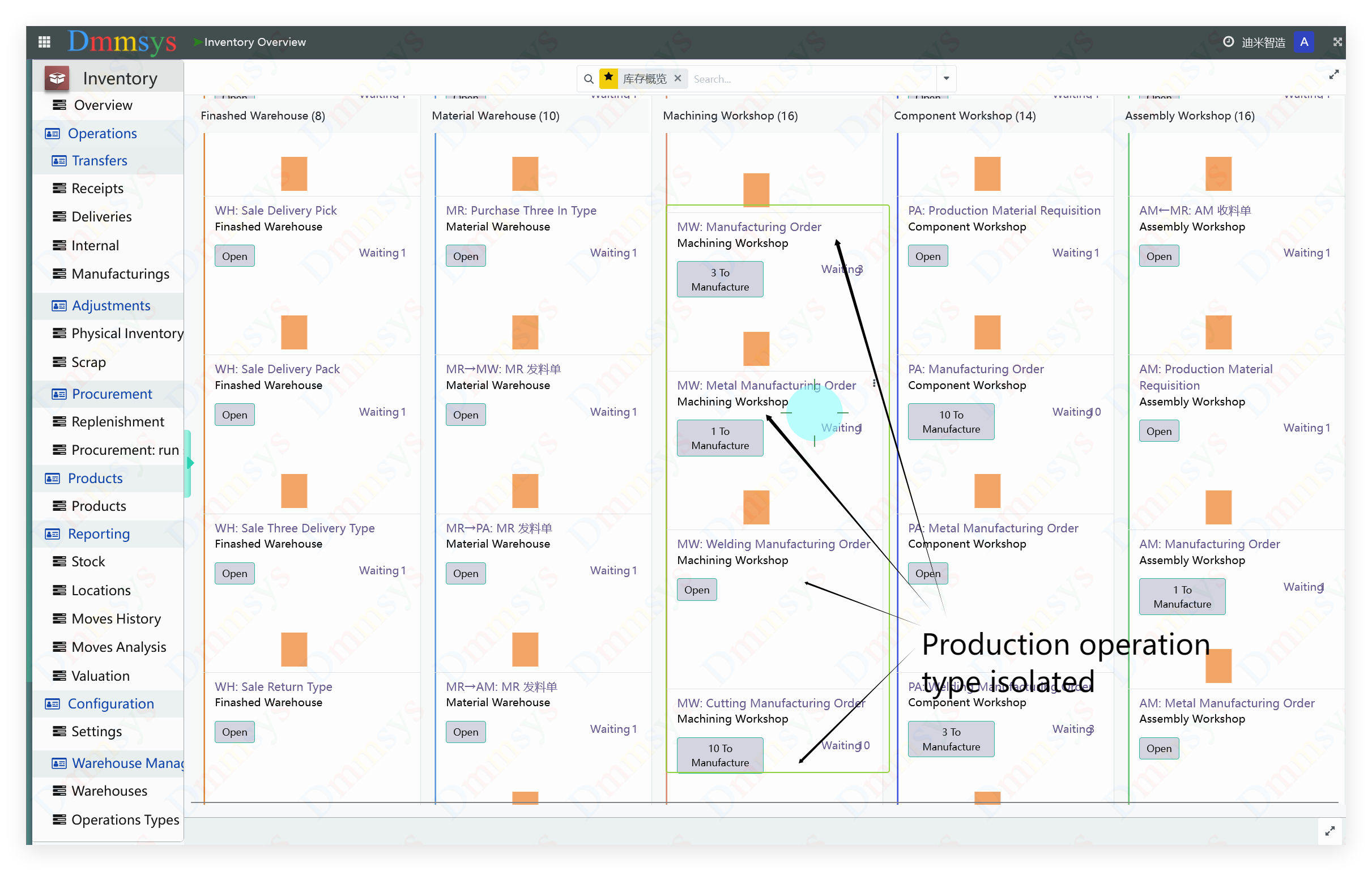

Multiple predefined types of manufacturing tasks enable easy isolation of manufacturing task order at the section level.Pre defined production picking types

By defining the manufacturing operation types of machining production orders, cutting production orders, welding production orders, sheet metal production orders, heat treatment production orders, and casting production orders in advance, To meet the job isolation of production orders at the workshop level in different scenarios of the manufacturing industry.

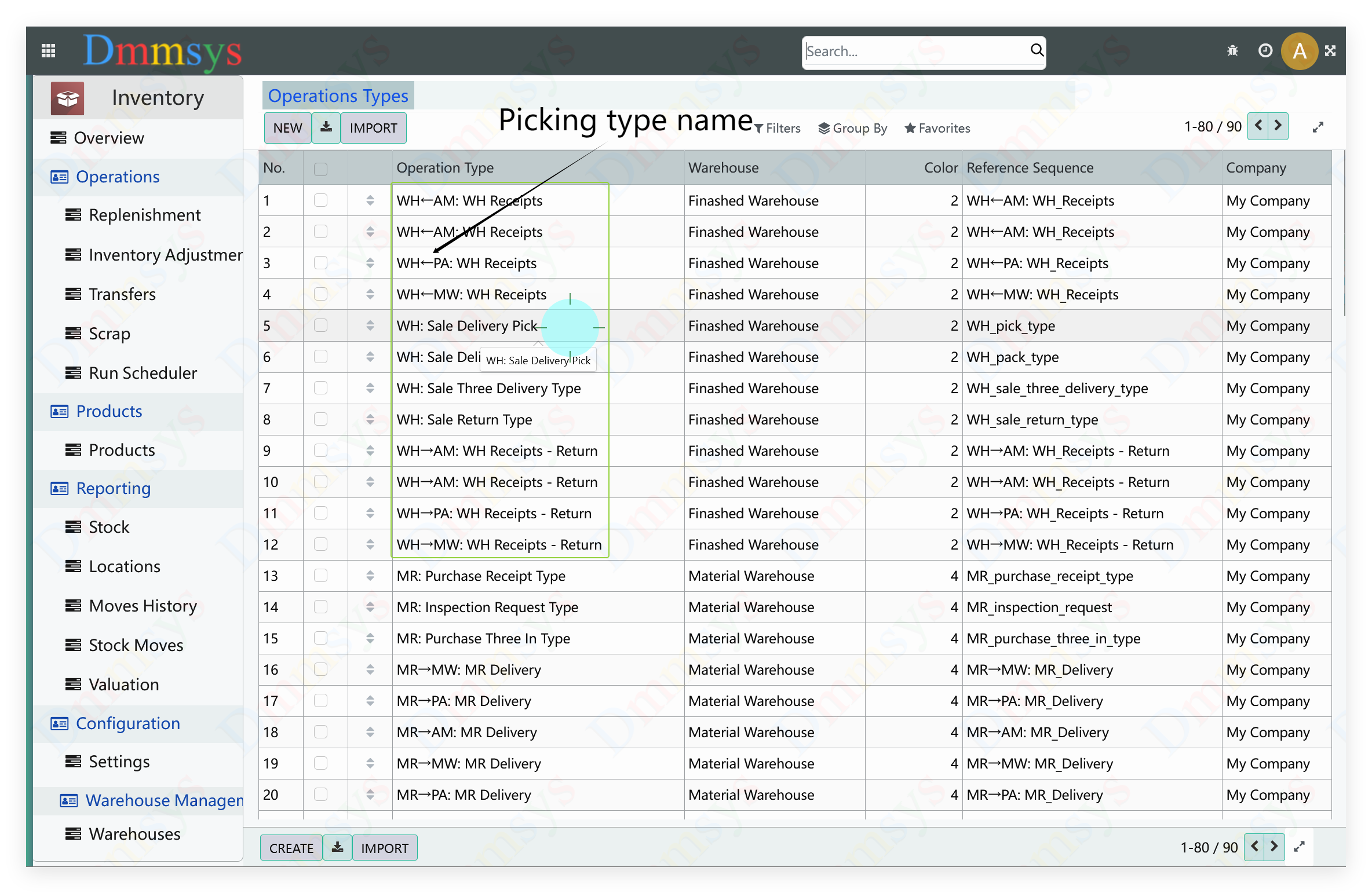

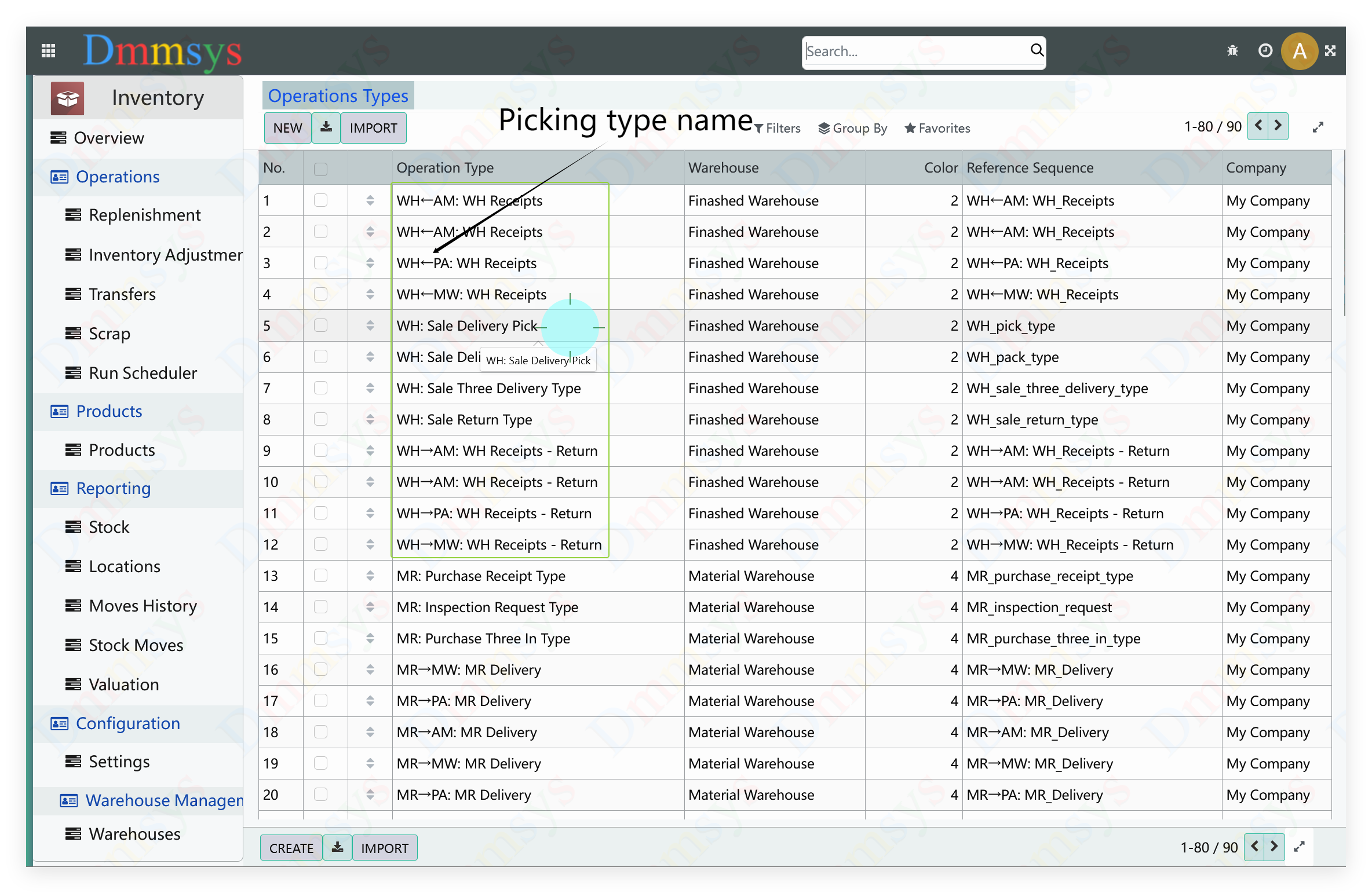

Friendly picking type name

The picking type adopts the naming method of warehouse code and picking type name, and accurately identifies the specific direction of the cross warehouse route on the name of the cross warehouse picking type route, To avoid confusion of picking ype names in complex business scenarios.

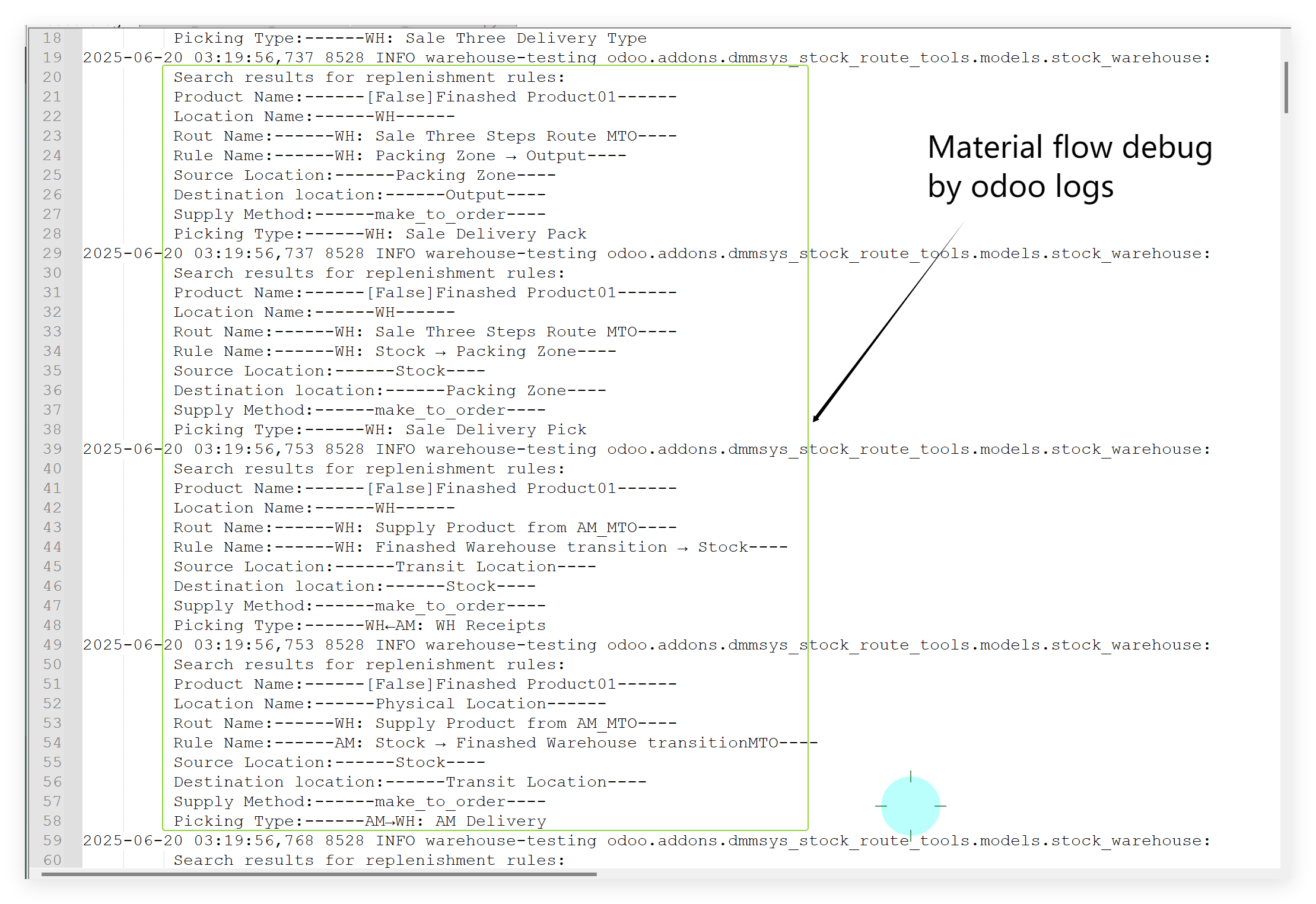

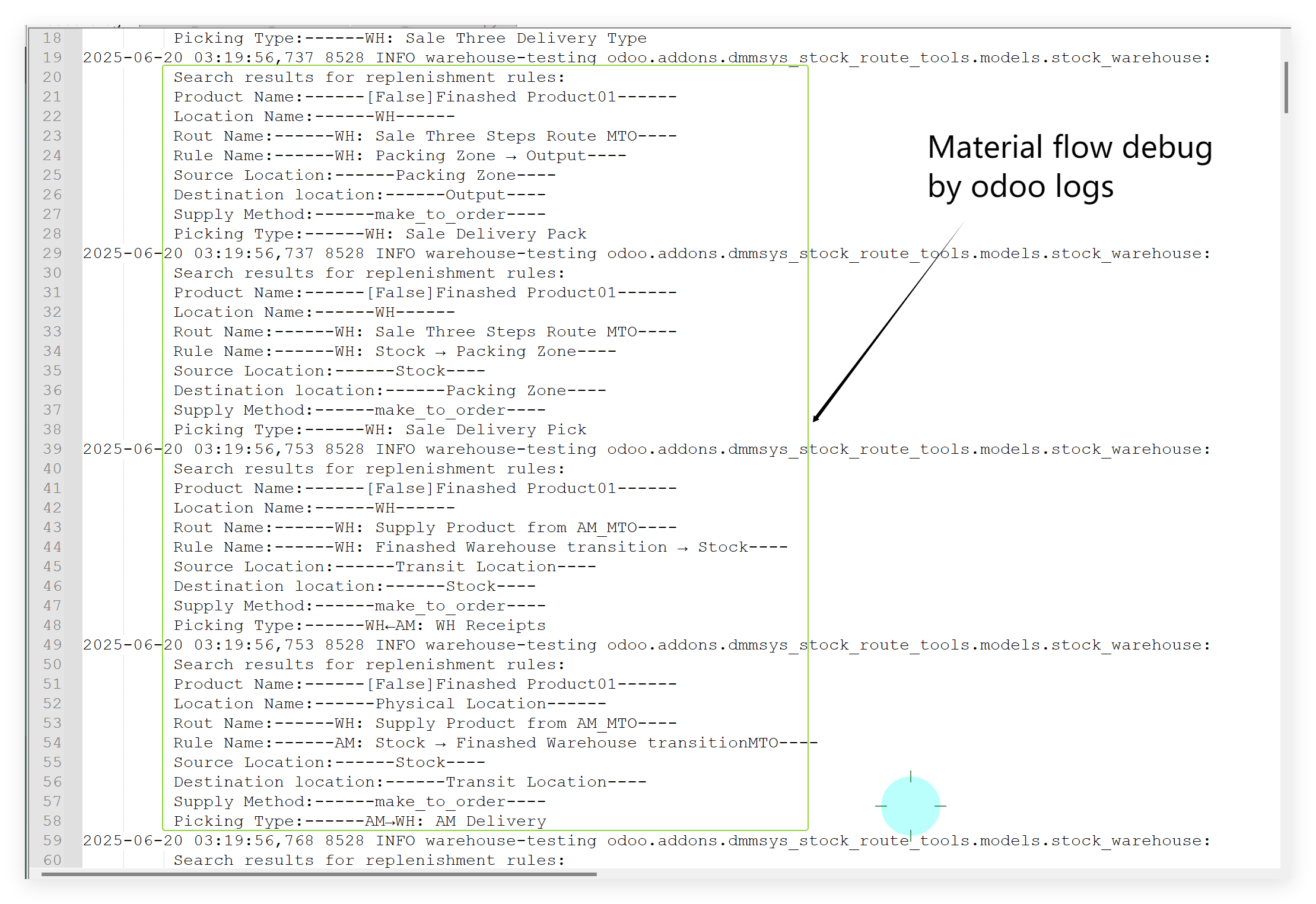

Debug the material route of all BOM structures through logs

Built in inventory routing debugging function, which can track the material replenishment process of each node in the entire BOM structure through logs, thereby solving possible routing problems..

模块功能列表

基于原生库存路线扩展开发的强大的路线配置工具.通过勾选仓库上的选项按钮,自动创建符合实际业务流程的所有的物料路线。

基础核心功能

库存路线配置工具,解决了原生库存路线存在的问题和不足。多步路线共存

通过将原生的多步路线的单选机制改为复选机制,实现了同一个仓库上,可以同时为不同分类的物料,配置不同步骤路线的功能。

例如,原料仓库对不需要质检控制的物料实现免检的两步入库路线,对必须质检的物料配置三步入库路线。 制造车间可以为车间中的初始始工段,配置先领料再生产的路线,为中间工段的生产单配置单步生产路线, 为最终入库的工段的生产单配置生产后必须质检的路线。

正确的跨仓库路线

通过开发精准的跨仓库路线,完美匹配实际业务中,位于BOM不同节点从而在多个仓库需要补货的同一个物料, 能够按照正确的流程和数量进行补货。

作业类型扩展

多种预定义的制造作业类型,轻松实现工段级别的制造作业单据隔离。预定义制造作业类型

通过预先定义的机加生成单、下料生产单、焊接生产单、钣金生产单、热处理生产单、铸造生产单的制造作业类型, 来满足不同场景下制造行业在车间工段级别的生产单的作业隔离。

友好的作业类型名称

作业类型采用了仓库编码加作业类型名称的命名方式,并在跨仓库作业路线名称上准确标识具体的跨仓库路线的方向, 从而避免复杂业务场景下作业类型名字的混淆。

通过日志调试所有BOM结构的物料路线

内置库存路线调试功能,通过日志可以跟踪整个BOM结构中每一个节点的物料补货的过程,从而解决可能存在的路线问题。。

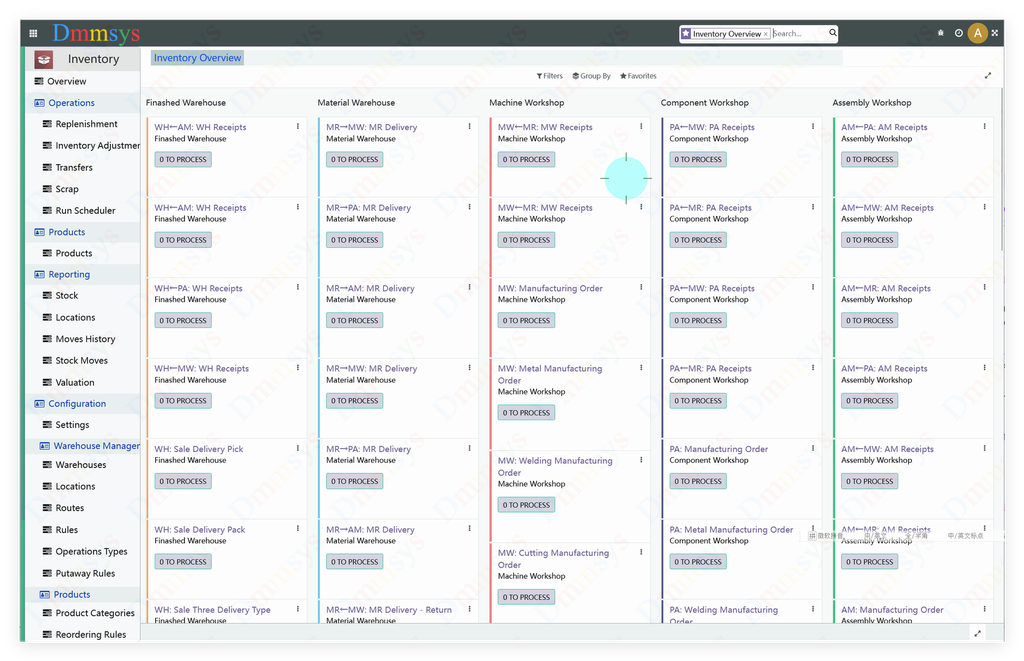

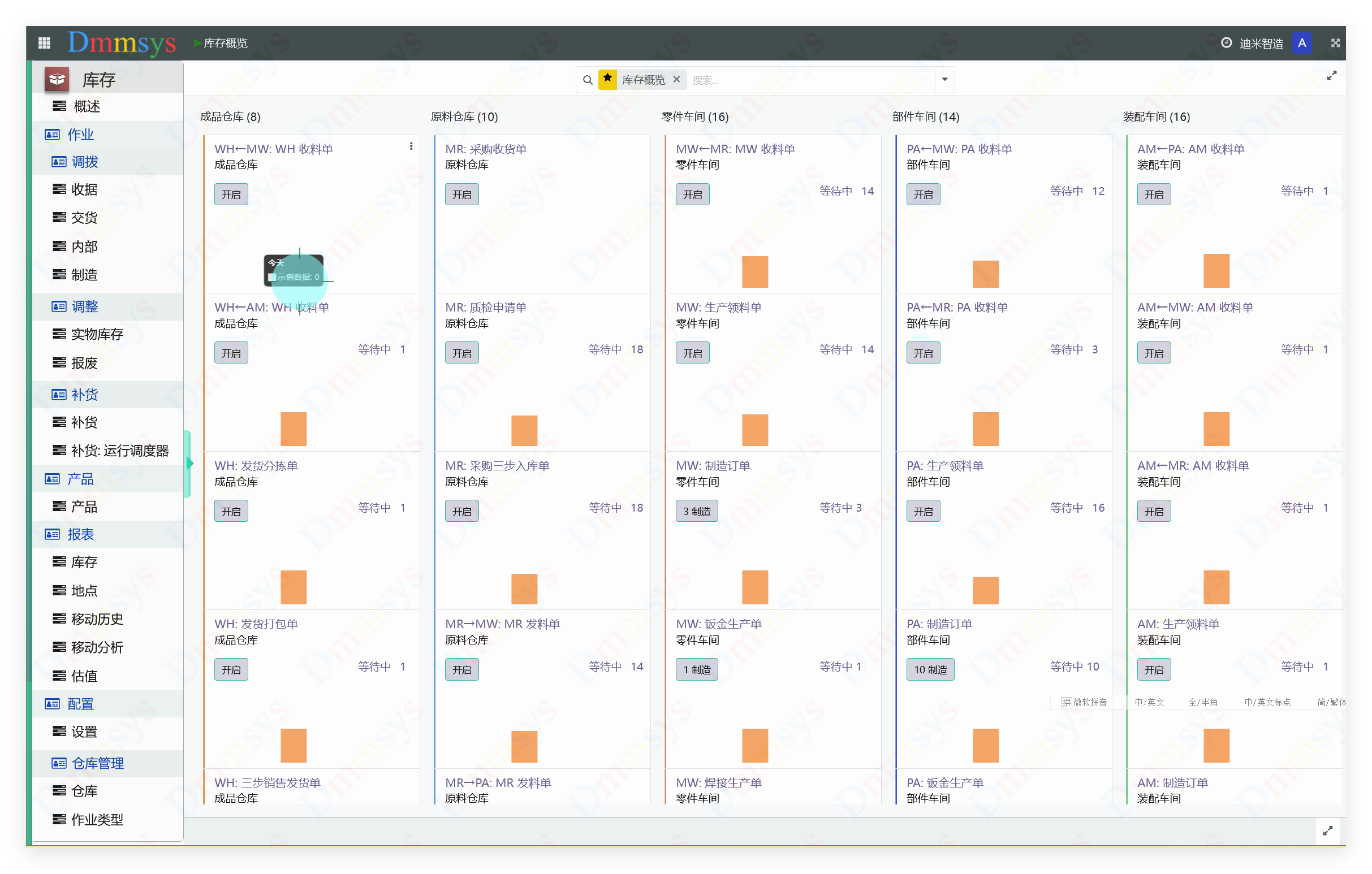

System Function Screenshot

No! Since the Odoo front-end has major changes in each version, all front-end modules do not support cross-version use.

According to Odoo's official policy, starting from version 13, each new version of the module needs to be purchased separately, if you need to upgrade the Odoo version, you need to repurchase our corresponding version of the module .

Yes, the module works well with Odoo Enterprise as well as Community. .

Yes, You can contact us through any way listed in the first part of the module description,such as email, skeype.

Suggested Products

Stock Route Configuration Tool

Odoo's inventory system is the core business underlying function of the entire ERP system. Different from traditional ERP systems' inventory, Odoo adopts inventory double entry bookkeeping,

Every inventory change (such as sales, purchases, transfers) will simultaneously record a decrease in the source storage location and an increase in the target storage location.

The Odoo inventory movement mechanism based on double entry bookkeeping realizes the entire production organization process, from the initial raw material procurement location to the final finished product delivery location for each level of material,

Forming a complete replenishment chain for material flow, Odoo uses material routes to match the flow process of each level of materials, thereby achieving a business process from the perspective of materials for the entire company.

However, the Odoo native inventory route has the following shortcomings and cannot fully meet the needs of the manufacturing industry for rapid configuration of business processes:

1. A warehouse can only execute one type of route, single step, two-step, or three-step cannot coexist.

2. When a material exists at different levels of BOM and is needed in multiple warehouses, it cannot be received and issued according to the actual business needs.

3. Unable to quickly configure the entire company's business processes, too many routes require manual creation.

To address the issues and shortcomings of the native features mentioned above,

we have developed a rapid process configuration tool.

Just check the option for multi-step routes on the warehouse to quickly create

all the picking types and stock routes required for complex business scenarios.

业务流程配置工具

Odoo的库存系统是整个ERP系统最核心的业务底层功能,区别于传统ERP系统的库存,Odoo采用库存复式记账,

每一笔库存变动(如销售、采购、调拨)都会同时记录源库位的减少和目标库位的增加。

基于复式记账的Odoo库存移动机制,实现了整个生产组织过程中,每一级物料,从最初的原料采购位置到最终成品交货的位置,

构成了一个完整的物料流动的补货链路,所以Odoo使用物料的路线,来匹配每一级物料的流动过程,从而实现整个公司的物料角度的业务流程。

但是Odoo原生库存路线存在下面的不足,不能完全满足制造行业快速配置业务流程的需求:

1、一个仓库只能执行一种步数的路线,单步,两步,或者三步不能共存。

2、当一个物料存在于bom不同层级,在多个仓库都需要时,不能按照业务实际的需求收料和发料。

3、不能快速实现整个公司业务流程的配置,太多的路线需要手工去创建。

为解决上述原生功能的问题及不足,我们开发了快速流程配置工具,只需要在仓库上勾选多步路线的选项,

就可以快速创建复杂业务场景所需的全部的作业类型和路线。

Key Feature

A powerful route configuration tool developed based on native inventory route expansion.By selecting the option button on the warehouse, it automatically creates all material routes that conform to the actual business process

Core route functions

The inventory route configuration tool solves the problems and shortcomings of the original inventory route..Coexistence of multi-step routes

By changing the original single selection mechanism of multi-step routes to a double selection mechanism, it is possible to configure different step routes for materials of different categories simultaneously in the same warehouse.

For example, the raw material warehouse implements a two-step inspection free storage route for materials that do not require quality control, and a three-step storage route for materials that require quality control. The manufacturing workshop can configure a route for material requisition and production for the initial starting section of the workshop, and a single step production route for production orders in the intermediate section, Configure a post production quality inspection route for the production order of the final warehouse section.

Unified Access Control

By developing precise cross warehouse routes and perfectly matching the same material that needs to be replenished in multiple warehouses at different BOM nodes in actual business, replenishment can be carried out according to the correct process and quantity.

Picking type extension

Multiple predefined types of manufacturing tasks enable easy isolation of manufacturing task order at the section level.Pre defined production picking types

By defining the manufacturing operation types of machining production orders, cutting production orders, welding production orders, sheet metal production orders, heat treatment production orders, and casting production orders in advance, To meet the job isolation of production orders at the workshop level in different scenarios of the manufacturing industry.

Friendly picking type name

The picking type adopts the naming method of warehouse code and picking type name, and accurately identifies the specific direction of the cross warehouse route on the name of the cross warehouse picking type route, To avoid confusion of picking ype names in complex business scenarios.

Debug the material route of all BOM structures through logs

Built in inventory routing debugging function, which can track the material replenishment process of each node in the entire BOM structure through logs, thereby solving possible routing problems..

模块功能列表

基于原生库存路线扩展开发的强大的路线配置工具.通过勾选仓库上的选项按钮,自动创建符合实际业务流程的所有的物料路线。

基础核心功能

库存路线配置工具,解决了原生库存路线存在的问题和不足。多步路线共存

通过将原生的多步路线的单选机制改为复选机制,实现了同一个仓库上,可以同时为不同分类的物料,配置不同步骤路线的功能。

例如,原料仓库对不需要质检控制的物料实现免检的两步入库路线,对必须质检的物料配置三步入库路线。 制造车间可以为车间中的初始始工段,配置先领料再生产的路线,为中间工段的生产单配置单步生产路线, 为最终入库的工段的生产单配置生产后必须质检的路线。

正确的跨仓库路线

通过开发精准的跨仓库路线,完美匹配实际业务中,位于BOM不同节点从而在多个仓库需要补货的同一个物料, 能够按照正确的流程和数量进行补货。

作业类型扩展

多种预定义的制造作业类型,轻松实现工段级别的制造作业单据隔离。预定义制造作业类型

通过预先定义的机加生成单、下料生产单、焊接生产单、钣金生产单、热处理生产单、铸造生产单的制造作业类型, 来满足不同场景下制造行业在车间工段级别的生产单的作业隔离。

友好的作业类型名称

作业类型采用了仓库编码加作业类型名称的命名方式,并在跨仓库作业路线名称上准确标识具体的跨仓库路线的方向, 从而避免复杂业务场景下作业类型名字的混淆。

通过日志调试所有BOM结构的物料路线

内置库存路线调试功能,通过日志可以跟踪整个BOM结构中每一个节点的物料补货的过程,从而解决可能存在的路线问题。。

System Function Screenshot

No! Since the Odoo front-end has major changes in each version, all front-end modules do not support cross-version use.

According to Odoo's official policy, starting from version 13, each new version of the module needs to be purchased separately, if you need to upgrade the Odoo version, you need to repurchase our corresponding version of the module .

Yes, the module works well with Odoo Enterprise as well as Community. .

Yes, You can contact us through any way listed in the first part of the module description,such as email, skeype.