Dmmsys All in one PLM

Dmmsys 124358678@qq.comDmmsys Product LifeCycle Management

Product development management is the starting point of the business chain in the manufacturing industry.

Without accurate product and BOM (Bill of Materials) basic data provided by the product development process,

the ERP (Enterprise Resource Planning) system is likely to encounter issues during use due to confusion in product basic data,

which in turn may affect the normal operation of the business.

Different from traditional PLM systems, the primary objective of developing the Dmmsys PLM system is to achieve integrated digital management for the manufacturing industry, providing a unique source of product and BOM data for subsequent production and manufacturing organization processes. Secondly, it manages the individual achievements of engineers in research and development, design models, and 2D engineering drawings. From the perspective of overall manufacturing management, the content managed by the PLM system includes not only the 3D models and 2D engineering drawings delivered by engineers, but more importantly, the parameter data about products (materials) behind these deliverables, such as material, dimensions, tolerances, and design BOM data.

Dmmsys 产品生命周期管理系统

产品开发管理是制造业业务链的起点。如果产品开发过程中没有提供准确的产品和BOM(物料清单)基础数据,

ERP(企业资源计划)系统在使用过程中可能会因产品基础数据混乱而遇到问题,进而影响业务的正常运行。.

与传统的PLM系统不同,开发Dmmsys PLM系统的主要目标是实现制造业的集成数字化管理,为后续的生产和制造组织过程提供独特的产品和BOM数据来源。 其次,它管理工程师在研发、设计模型和二维工程图纸方面的个人成就。从整体制造管理的角度来看, PLM系统管理的内容不仅包括工程师交付的3D模型和2D工程图纸,更重要的是, 这些交付成果背后的产品(材料)参数数据,如材料、尺寸、公差和设计BOM数据。

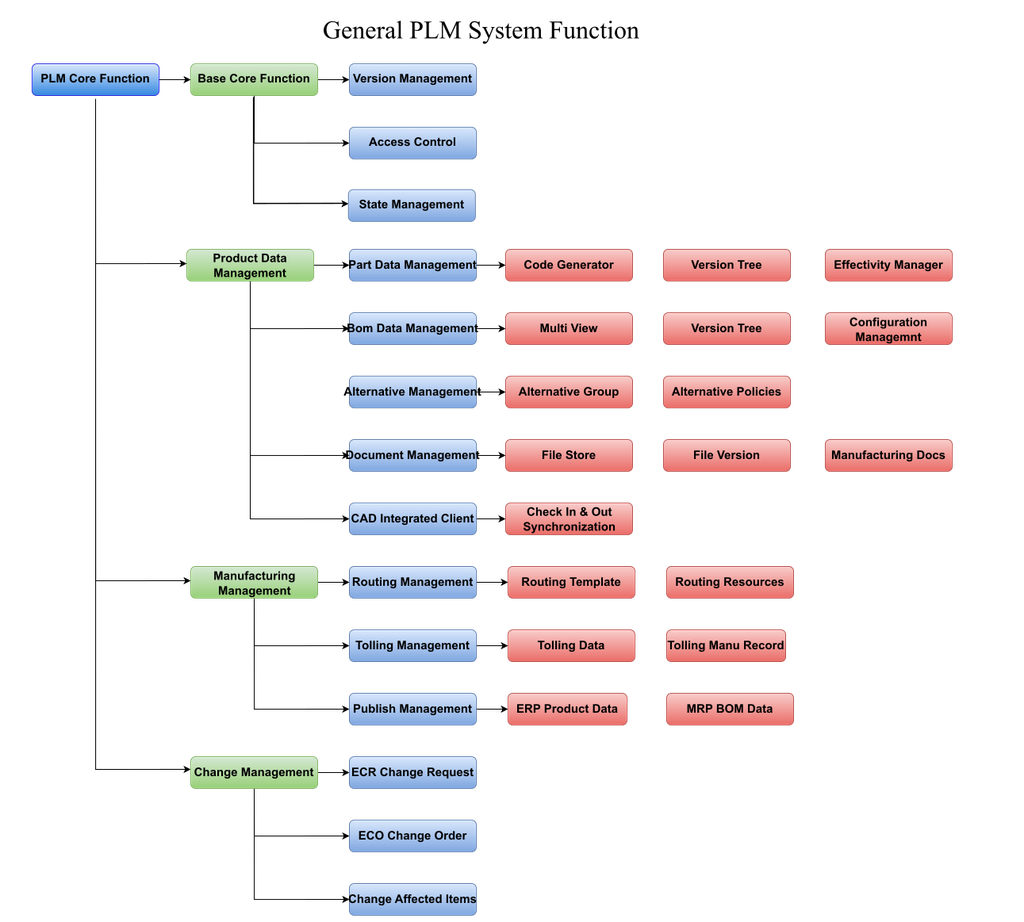

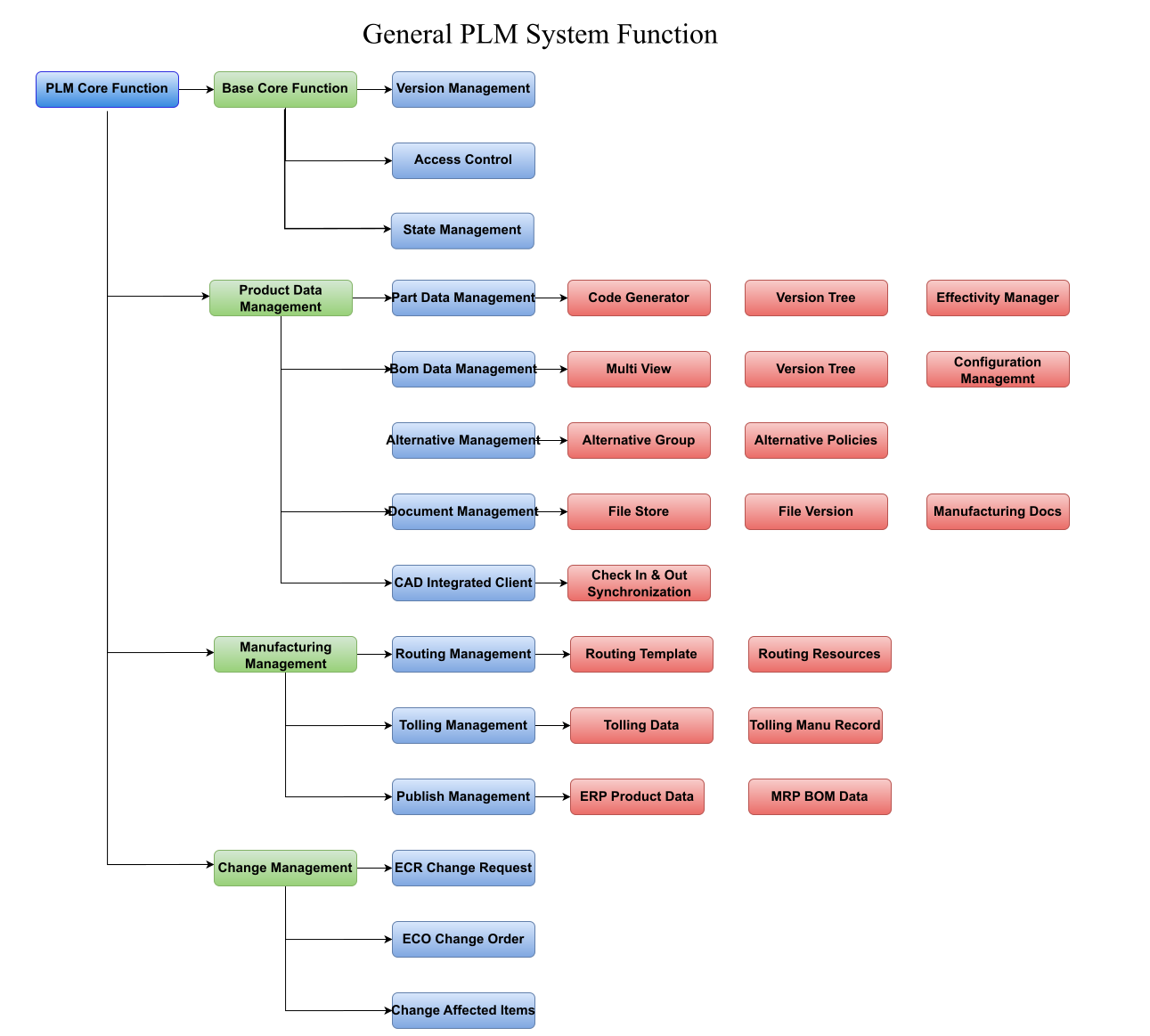

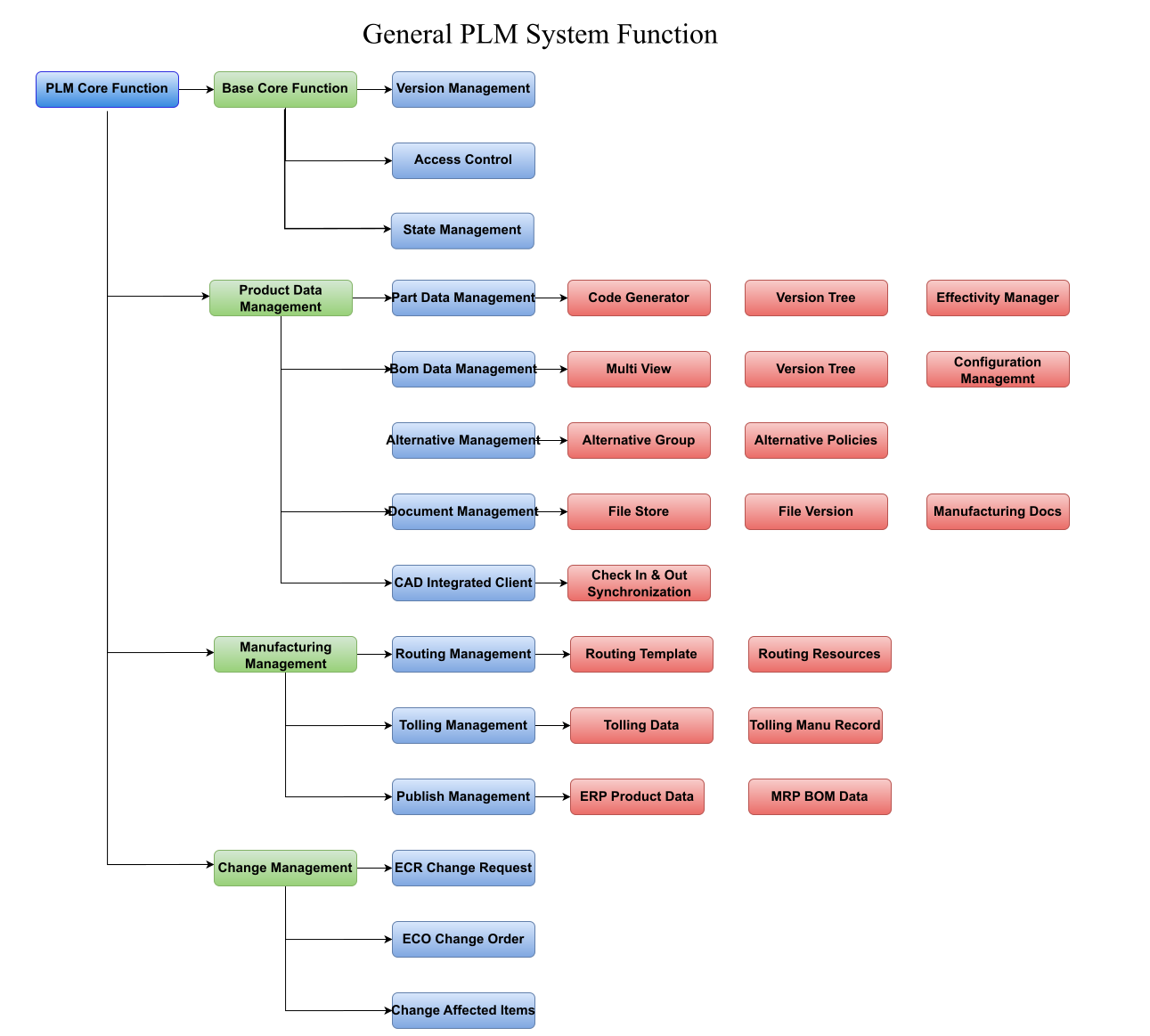

Key Feature

The DmmsysPLM system follows the functional planning and implementation mechanism of the Windchill system, Implemented the functions of global access control permission management at the bottom level, state management of business objects, and unified version management machine.Basic core functions

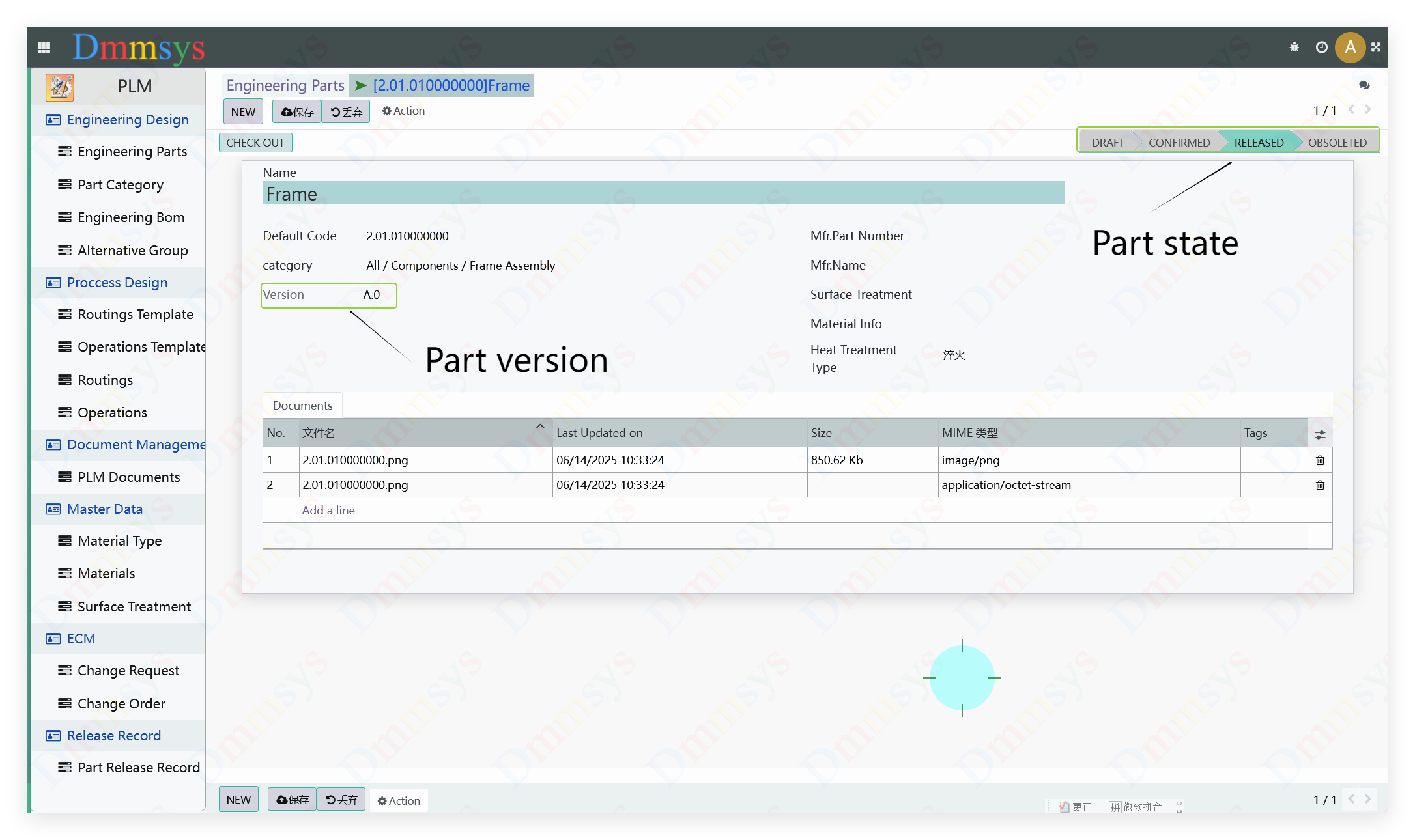

The DmmsysPLM system was developed and implemented based on the Odoo system, following the functional planning and implementation mechanism of the Windchill system.Unified Version Management

The underlying version management mechanism implements version control for all product development business objects. Versions are divided into large and small versions. Designers generate small versions every time they check in and out, and generate large versions every time they officially release.

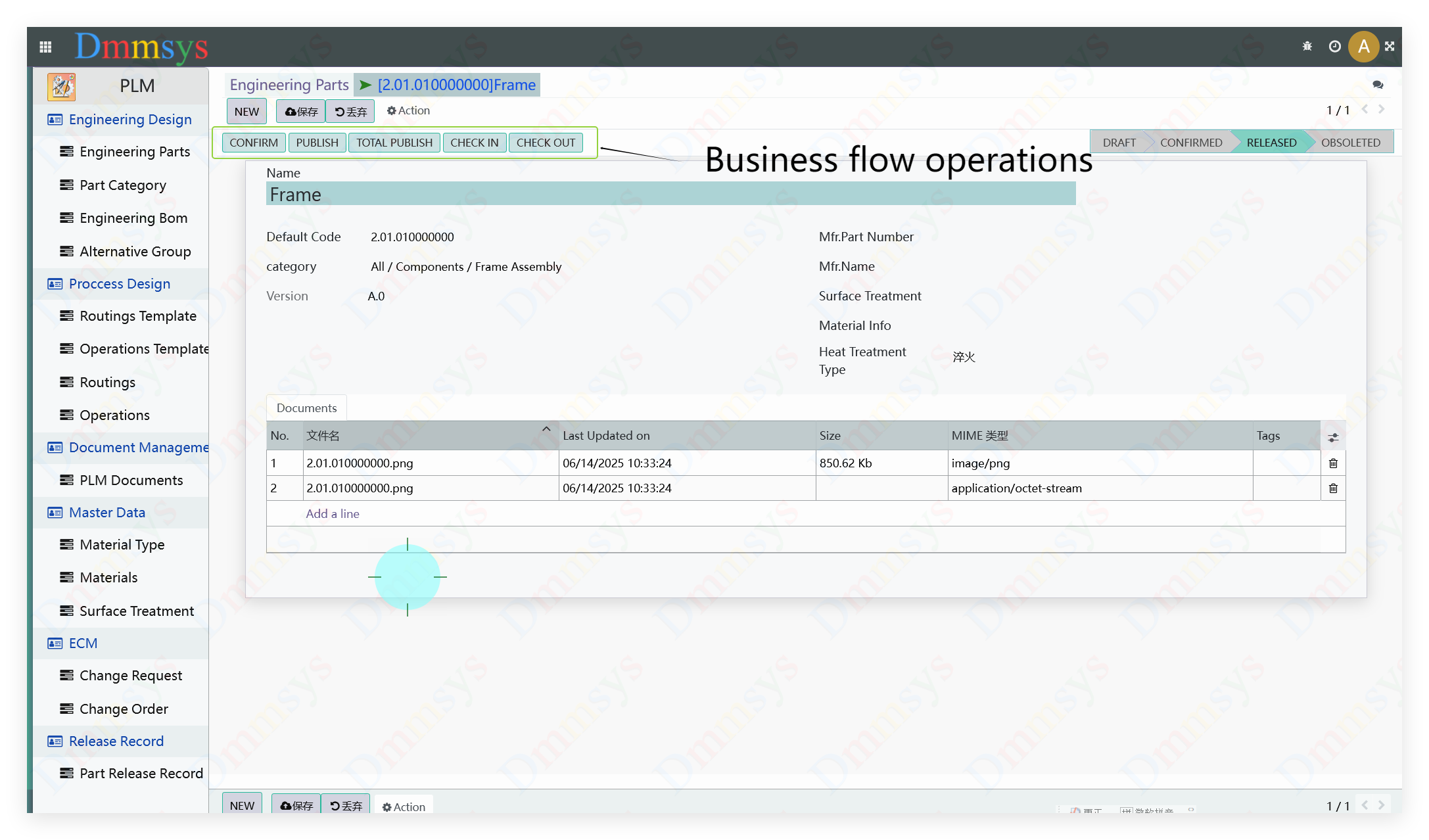

Unified Access Control

All key product development business objects, such as components, drawings, documents, and engineering BOMs, have a unified check-in and check-out access control mechanism. The underlying version management mechanism implements version control for all product development business objects. Versions are divided into large and small versions. Designers generate small versions every time they check in and out, and generate large versions every time they officially release.

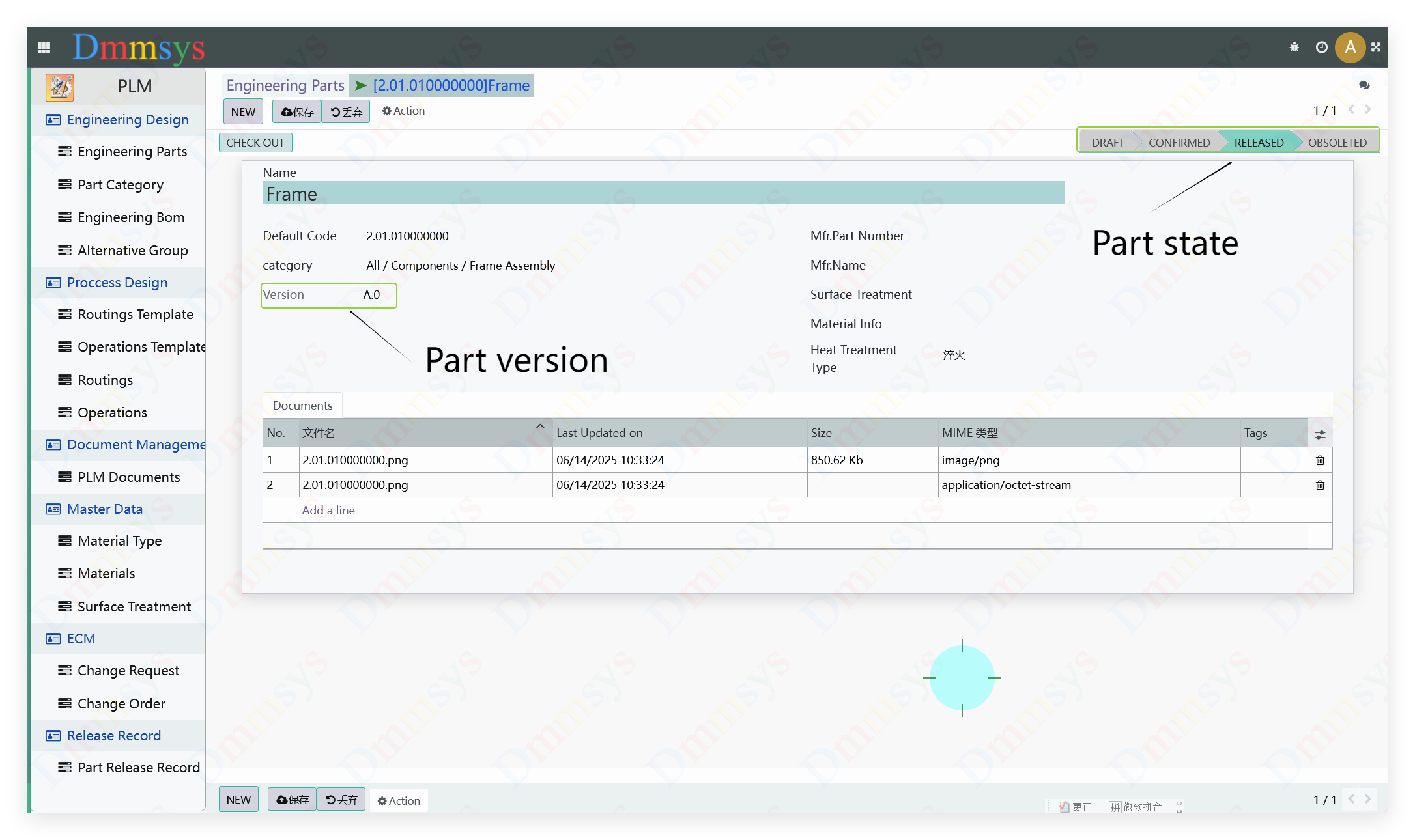

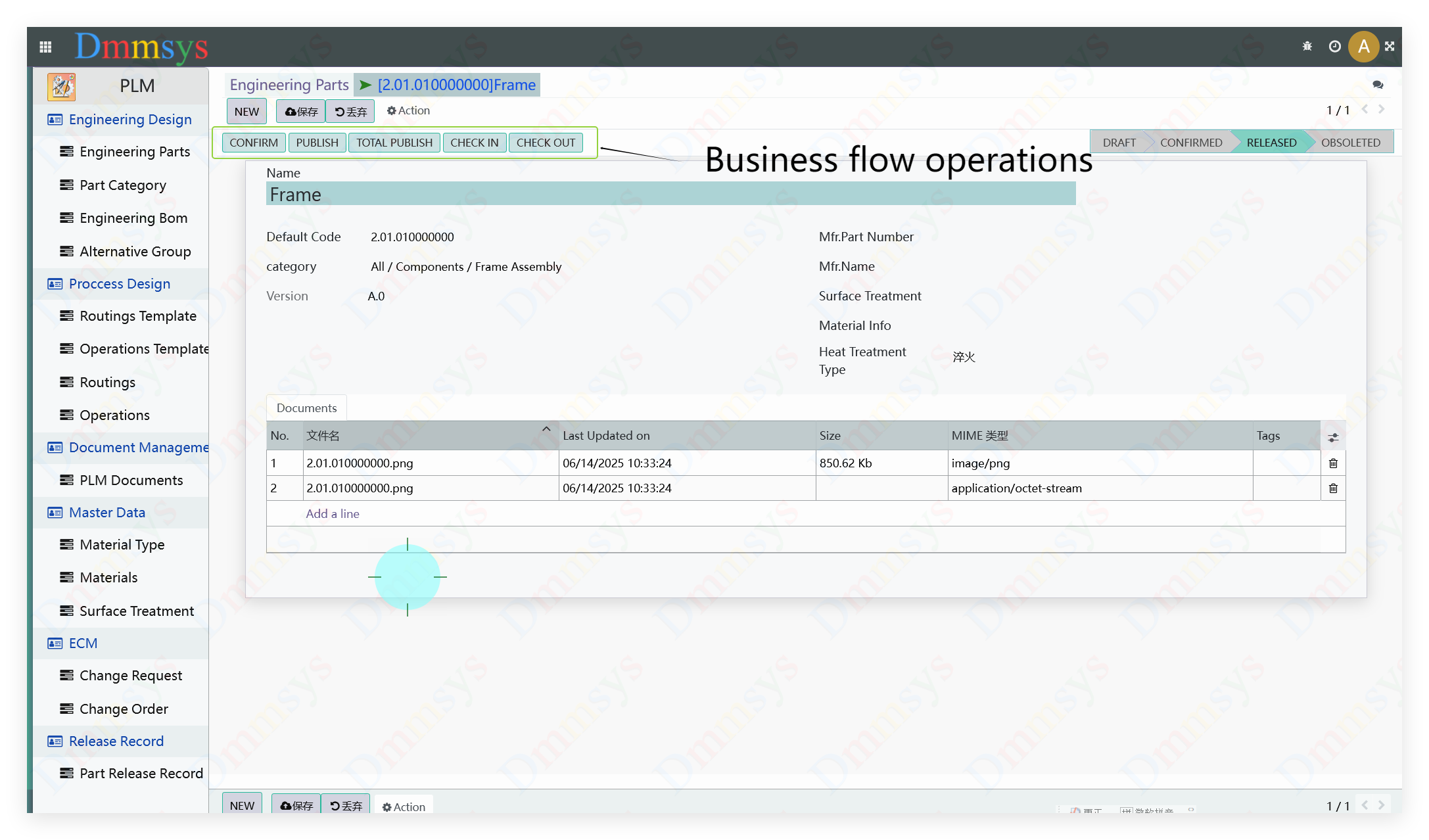

Unified State Management

All R&D objects have a unified state management mechanism, which achieves basic R&D workflow control through different operational actions and corresponding state transitions during the R&D process..

Product Data Management

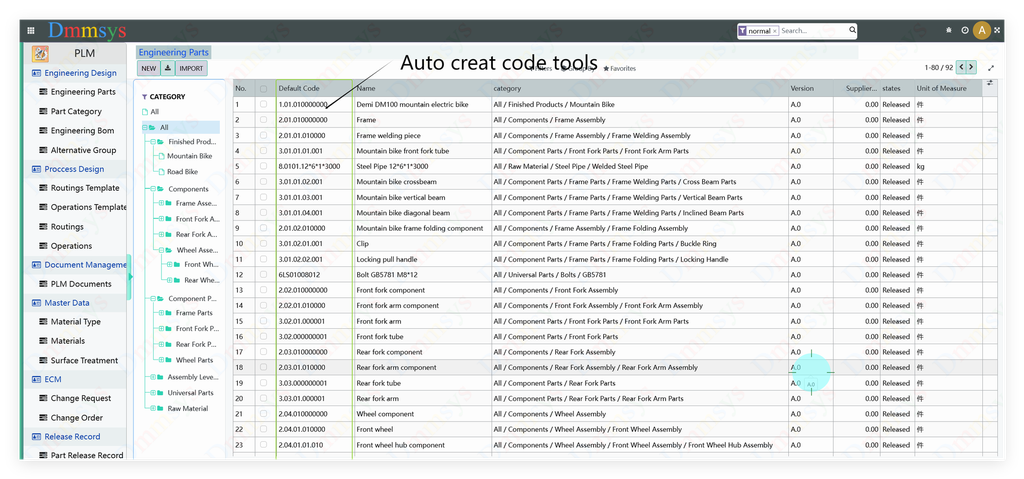

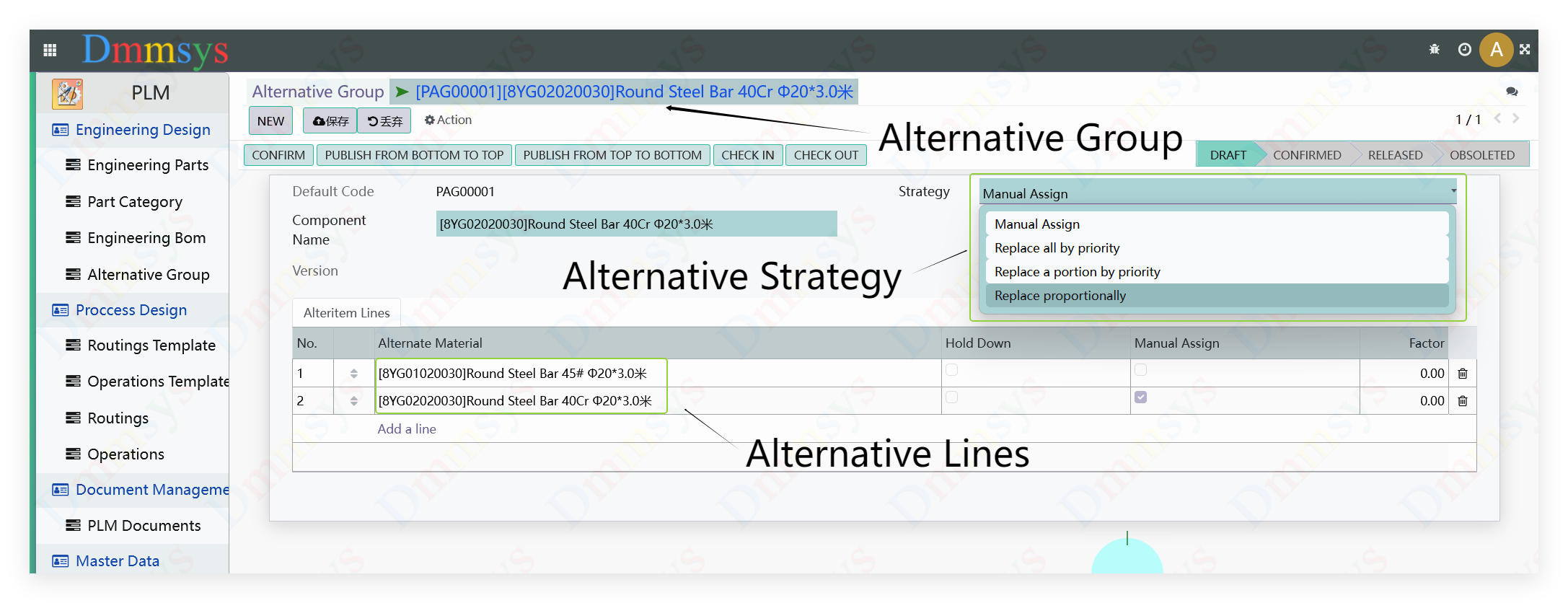

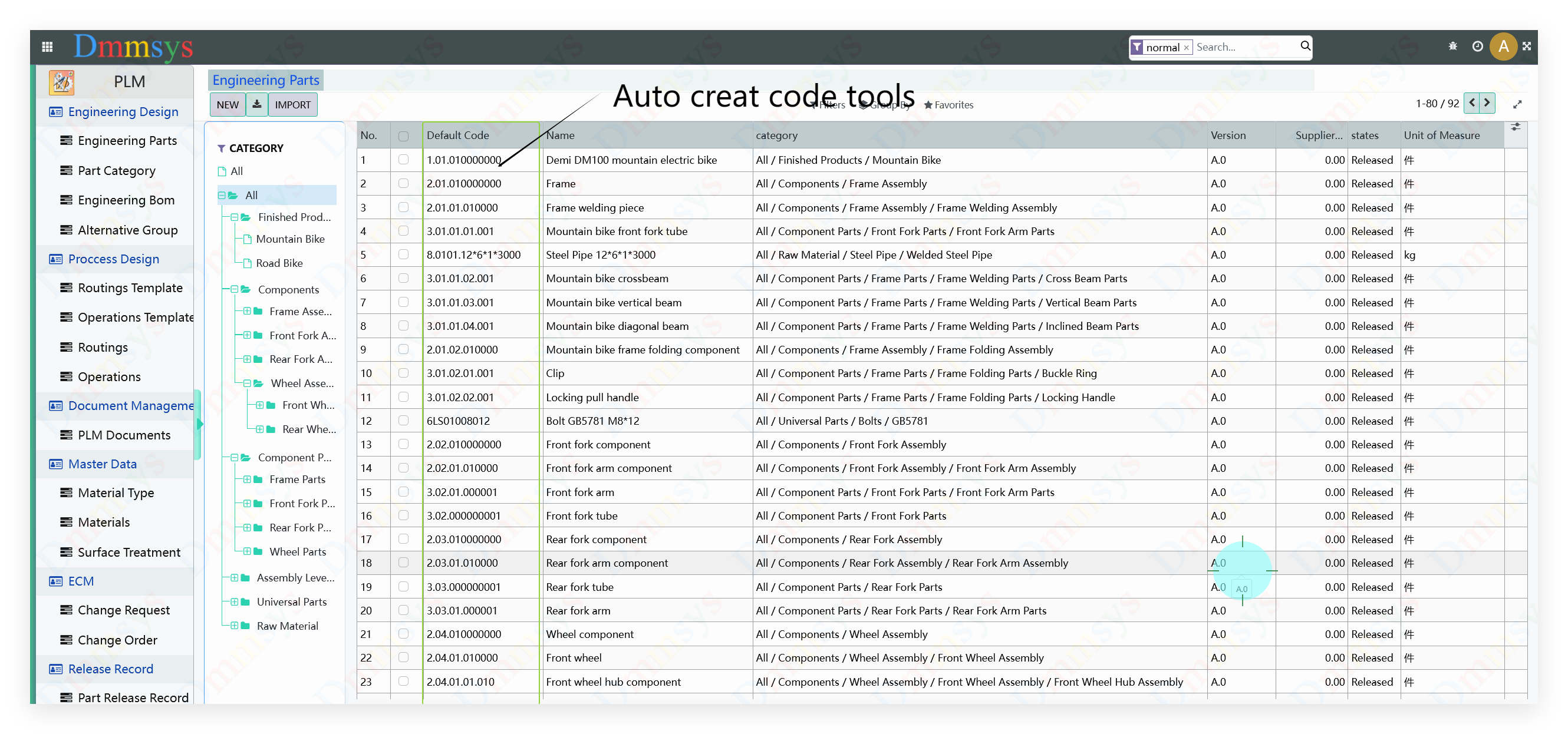

The PLM system originated from the PDM system, so product data management is the most core functional part of all PLM systems.Component Data Management

Component management includes basic functions such as automatic numbering of product components, version control of components, status control, and access control for check-in and check-out.

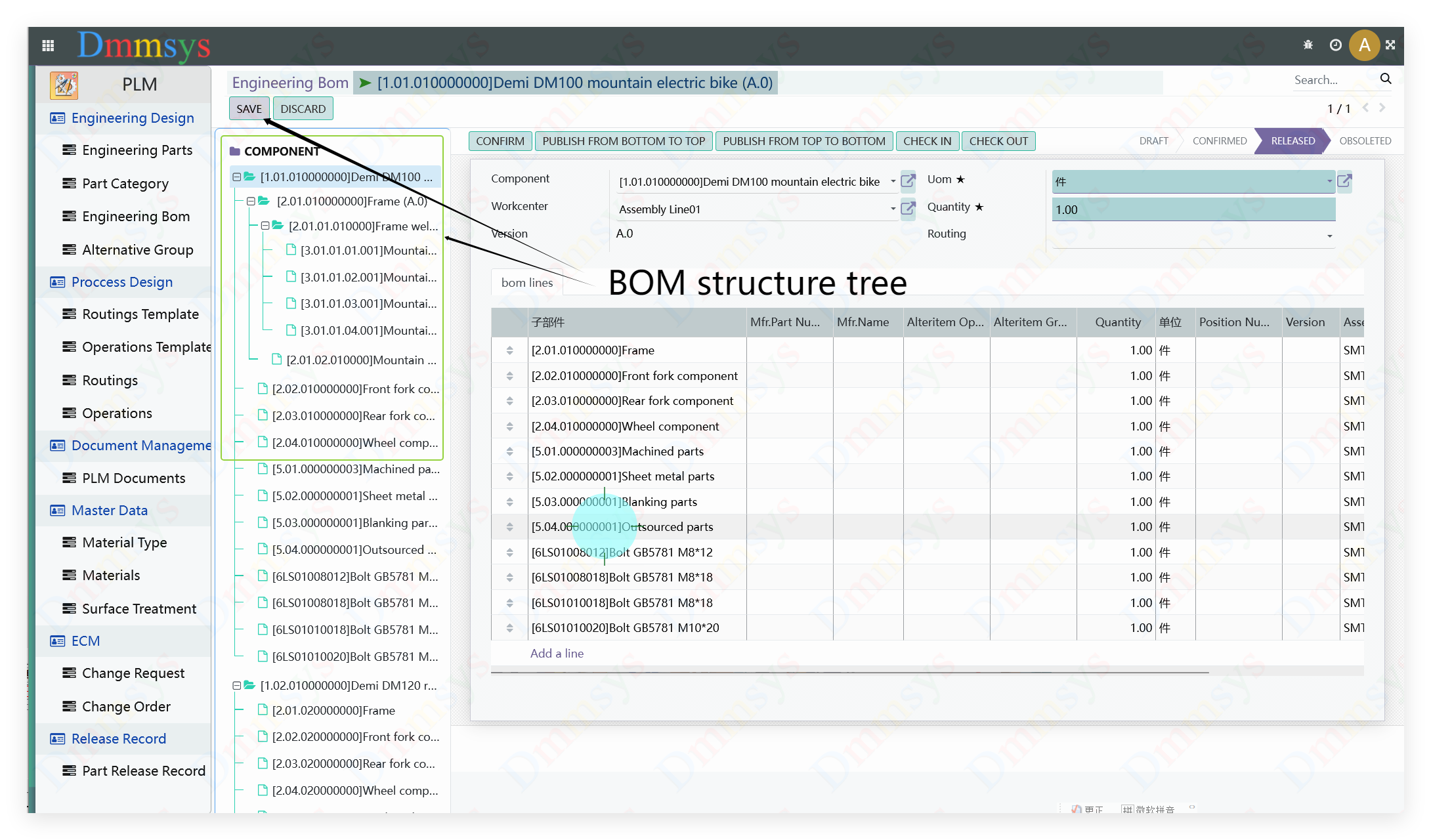

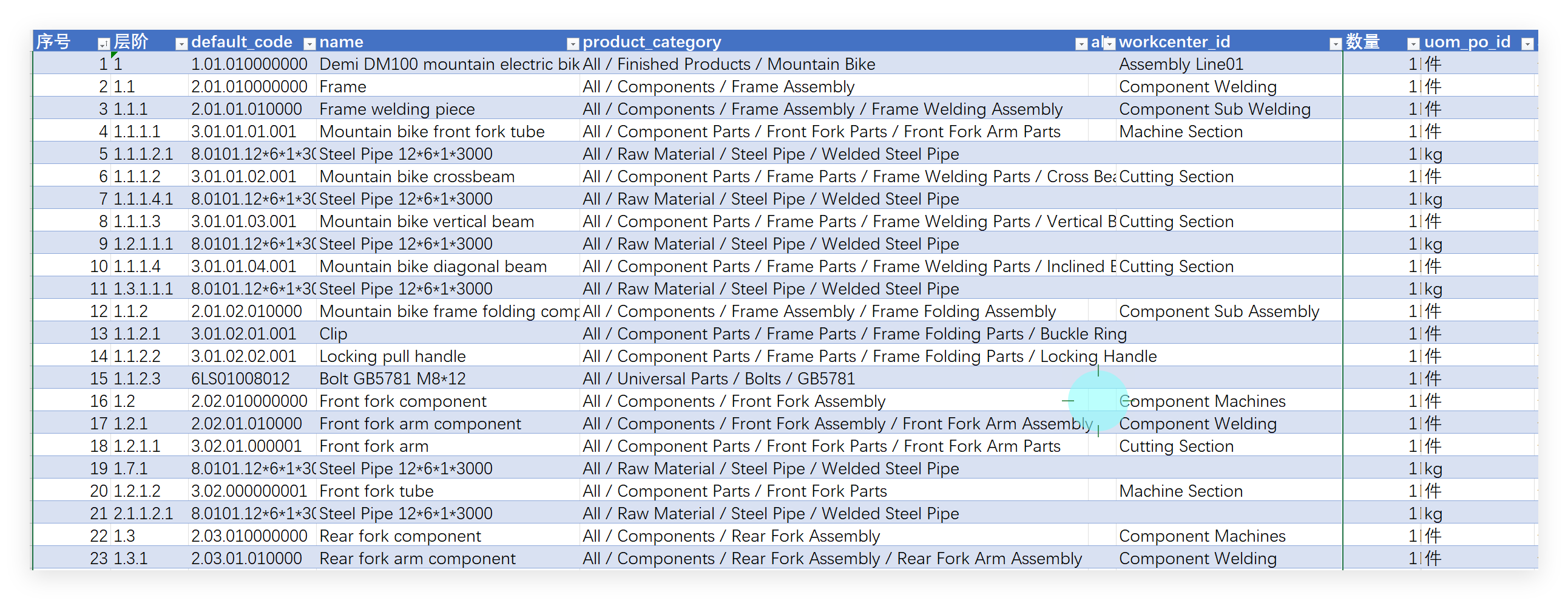

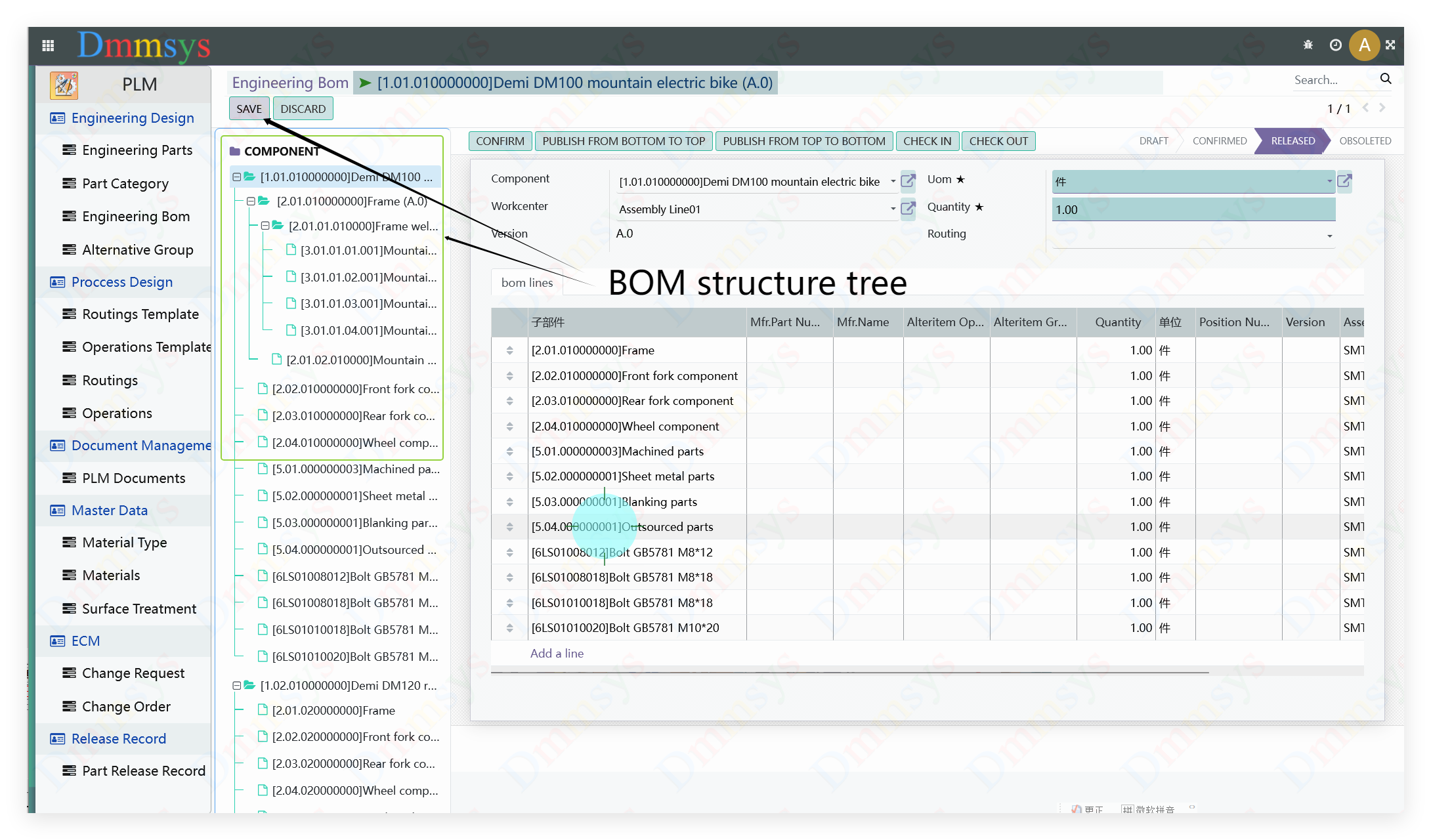

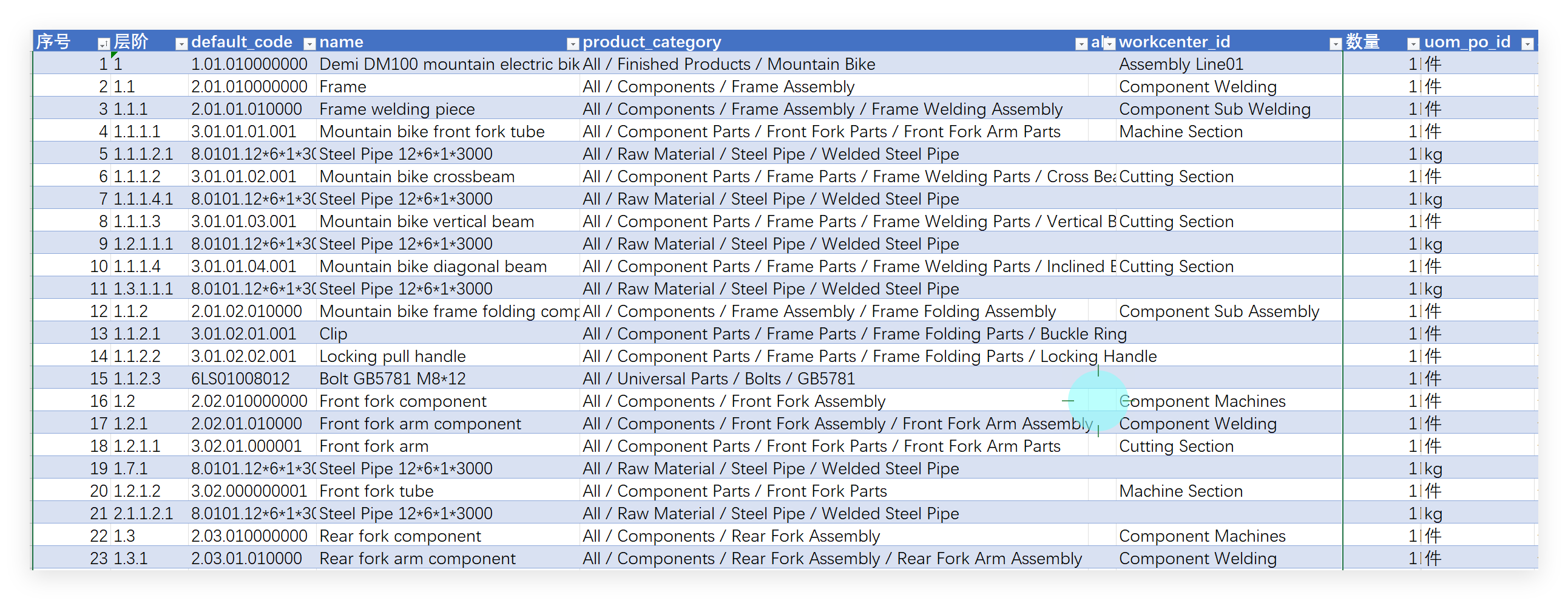

BOM Data Management

BOM is the data source of core manufacturing BOM, which not only determines the hierarchical dependency relationship of component manufacturing, but also determines the standard quota of each level of material.

BOM Structure Tree

The product structure tree function perfectly matches this top-down R&D process, and the entire process of creating the product structure tree can be completed on one page.

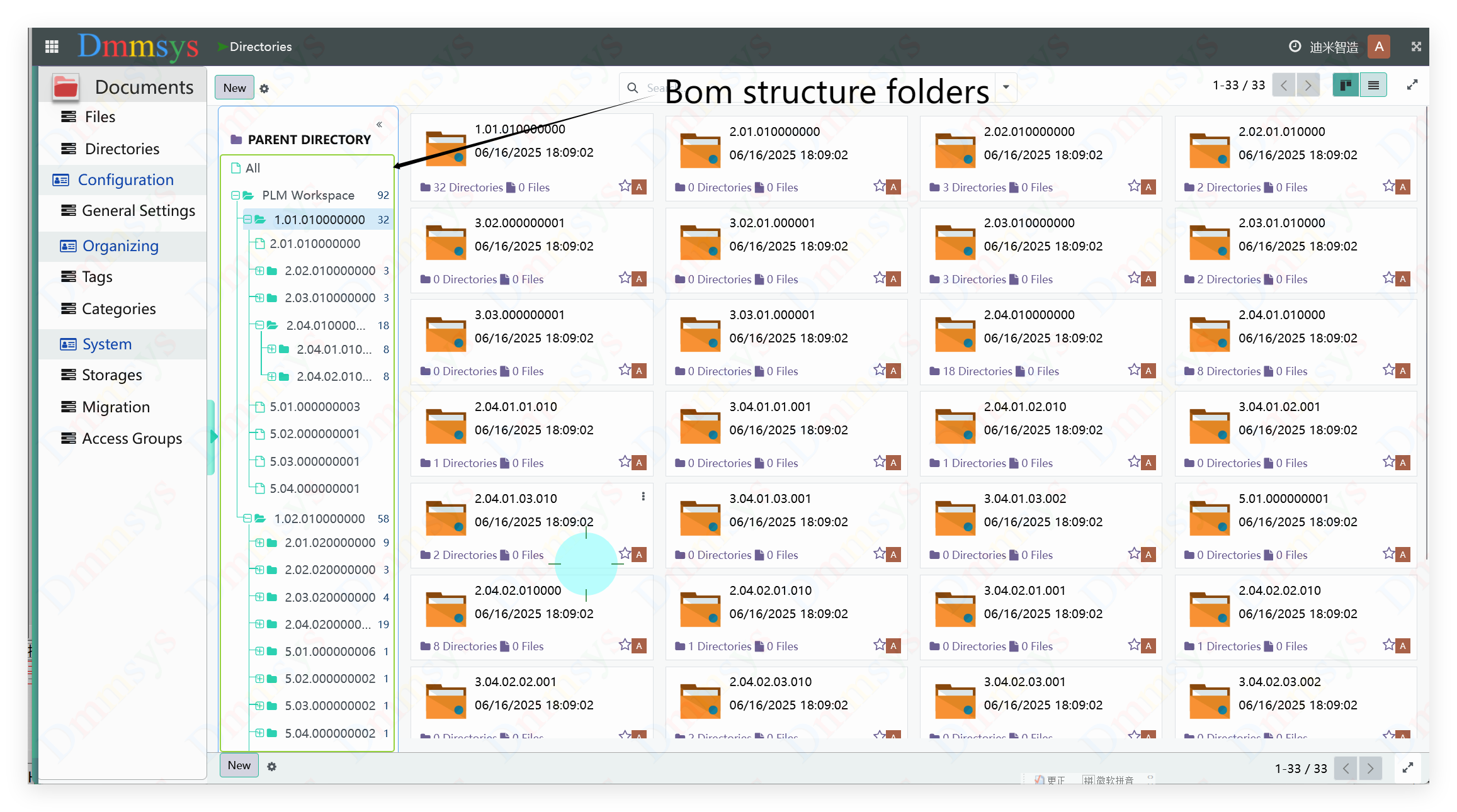

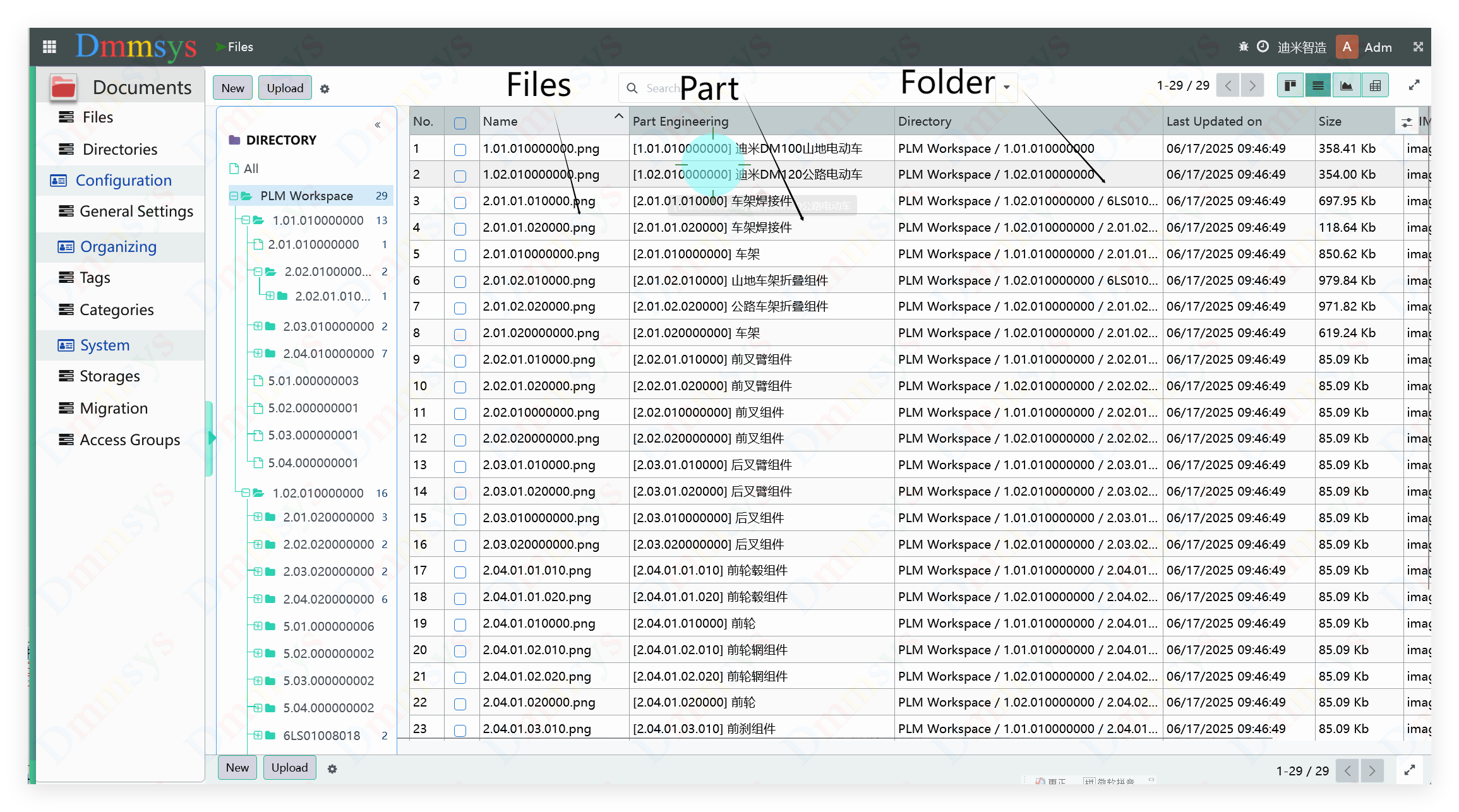

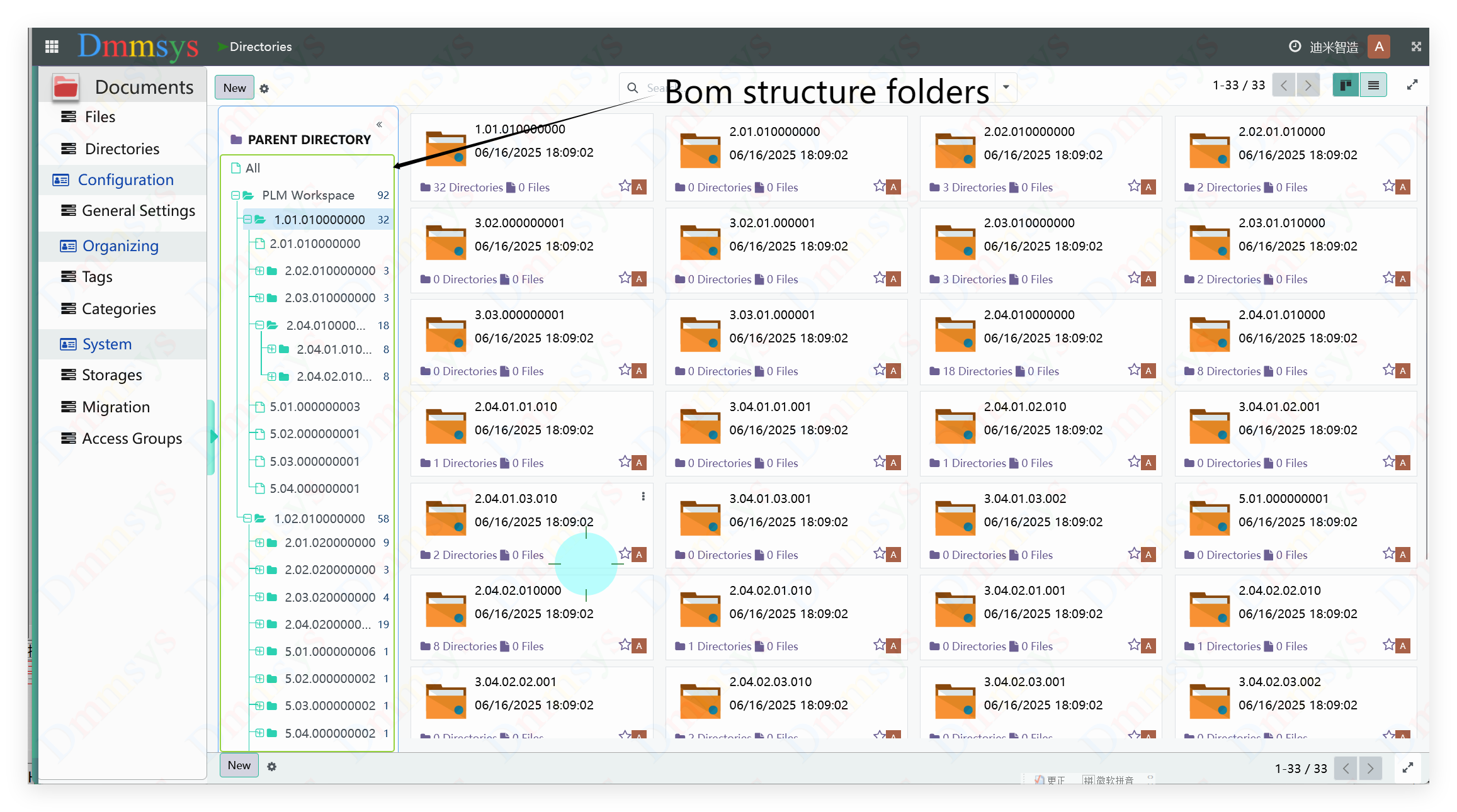

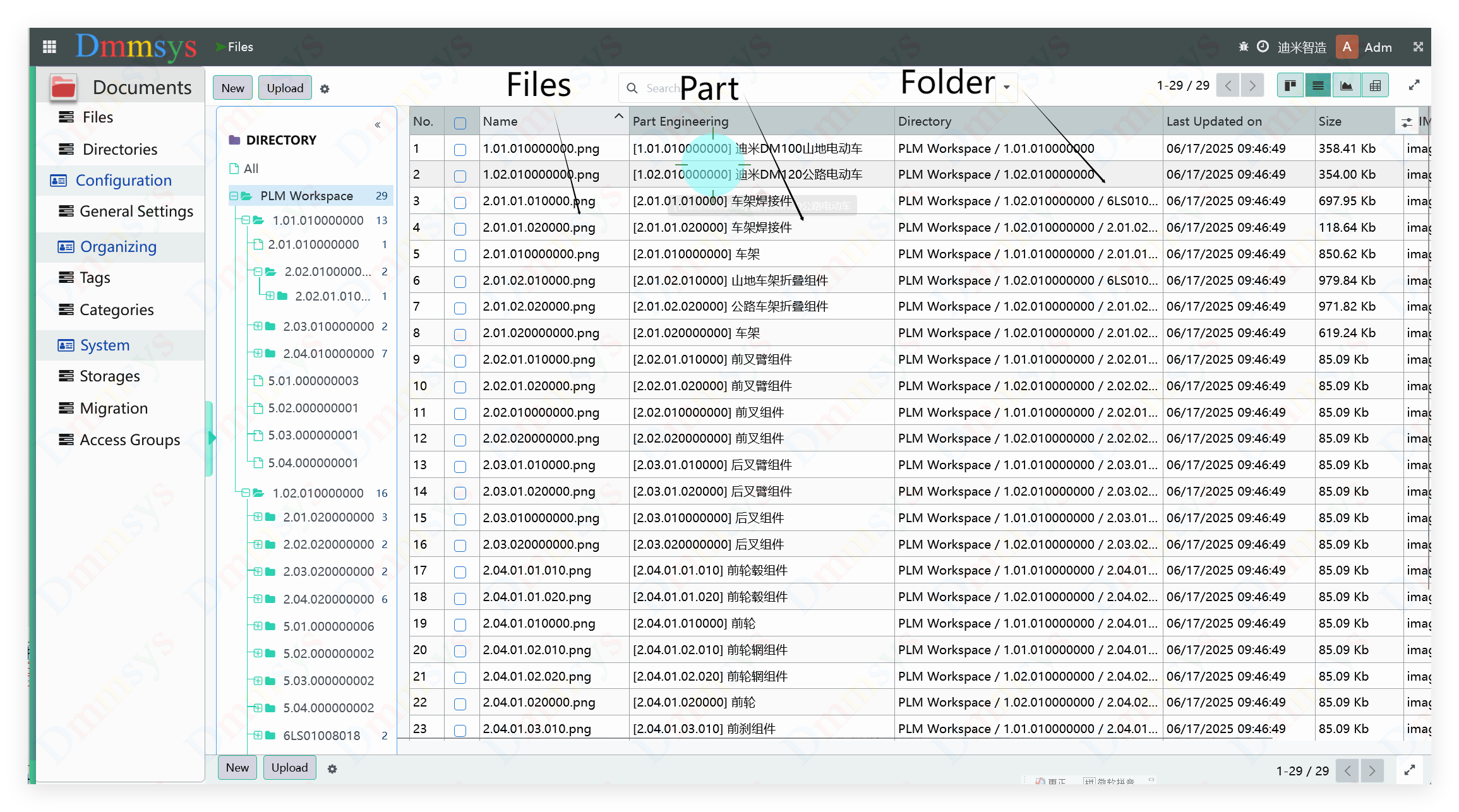

Drawing Document Management

On top of the DMS document management module based on OCA, we have carried out a series of functional extensions for PLM drawing document management to achieve the complete drawing document management function of the PLM system

Production Management

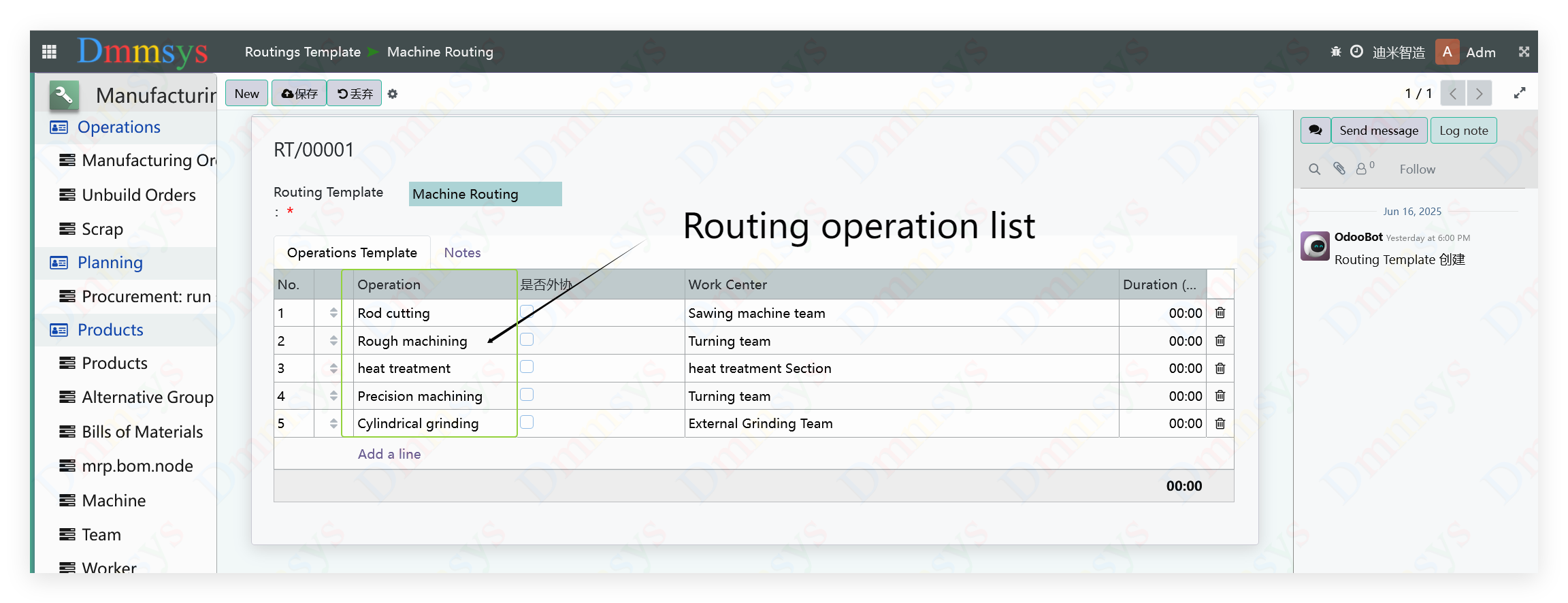

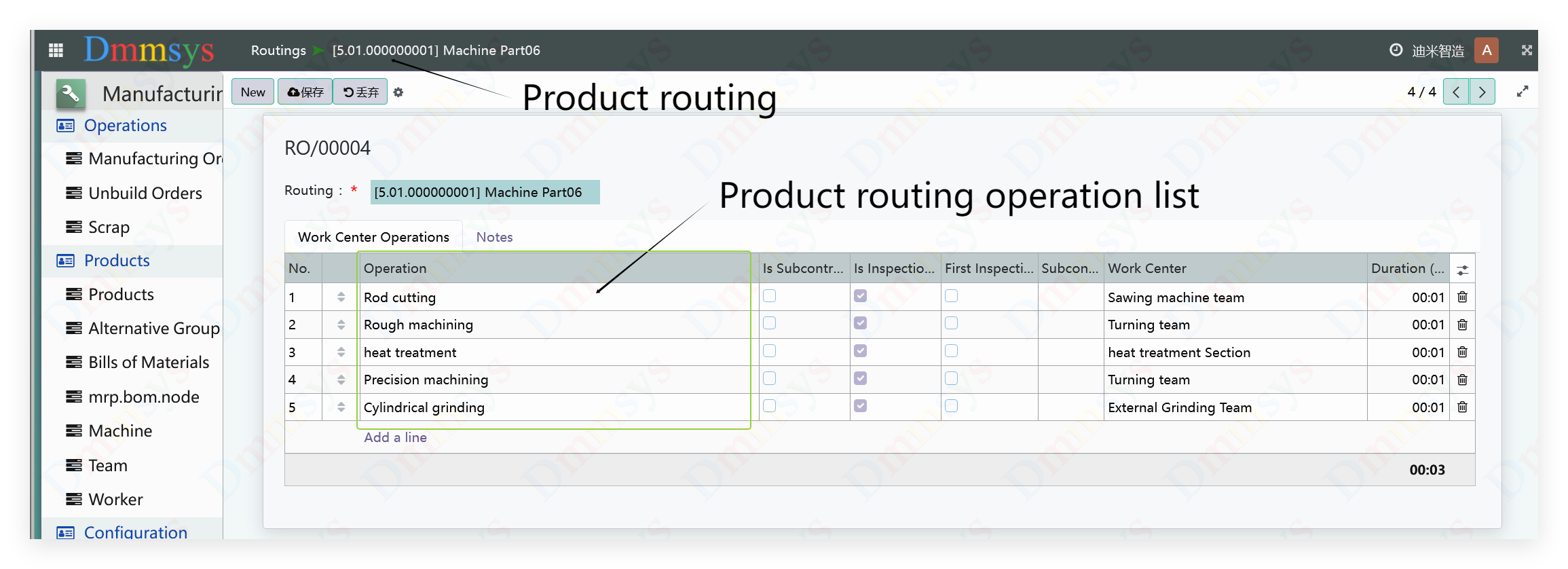

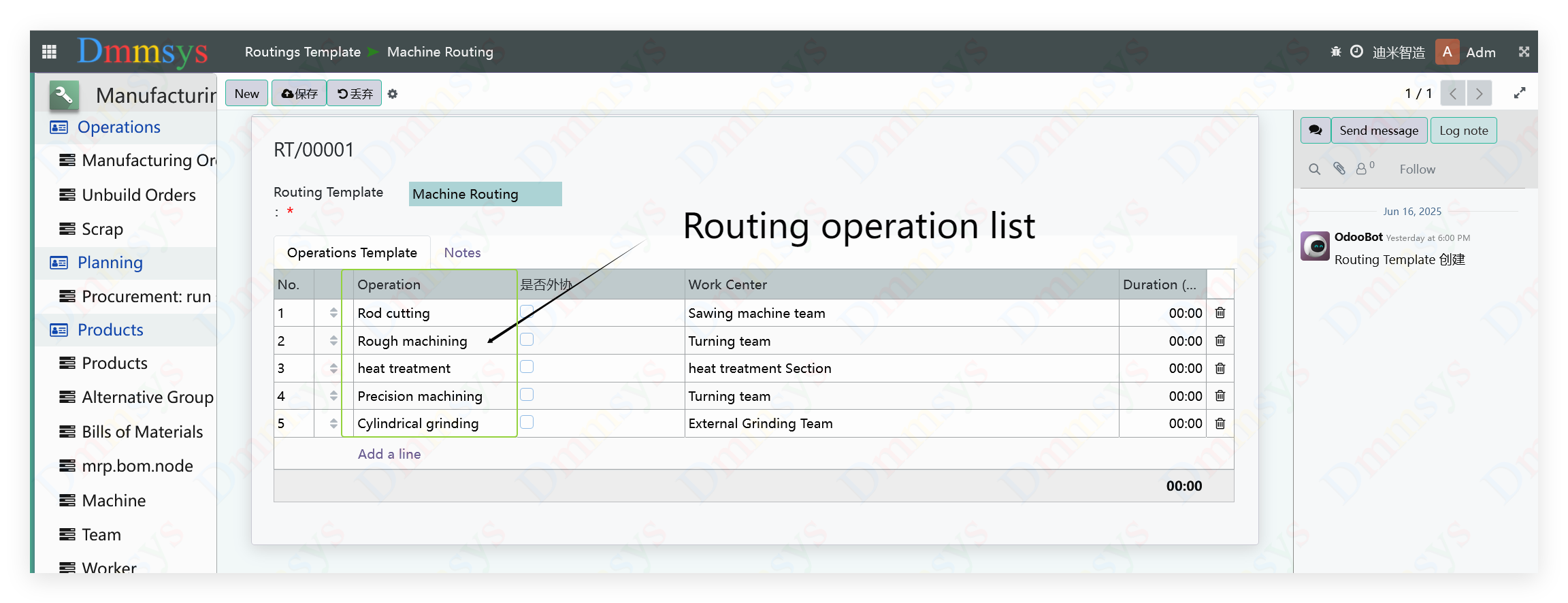

DmmsysPLM achieves rapid creation of process route instances through pre-defined process route templates classified by category.Mrp Routing Template

The process route template defines the general process steps for processing a type of component in actual business operations.

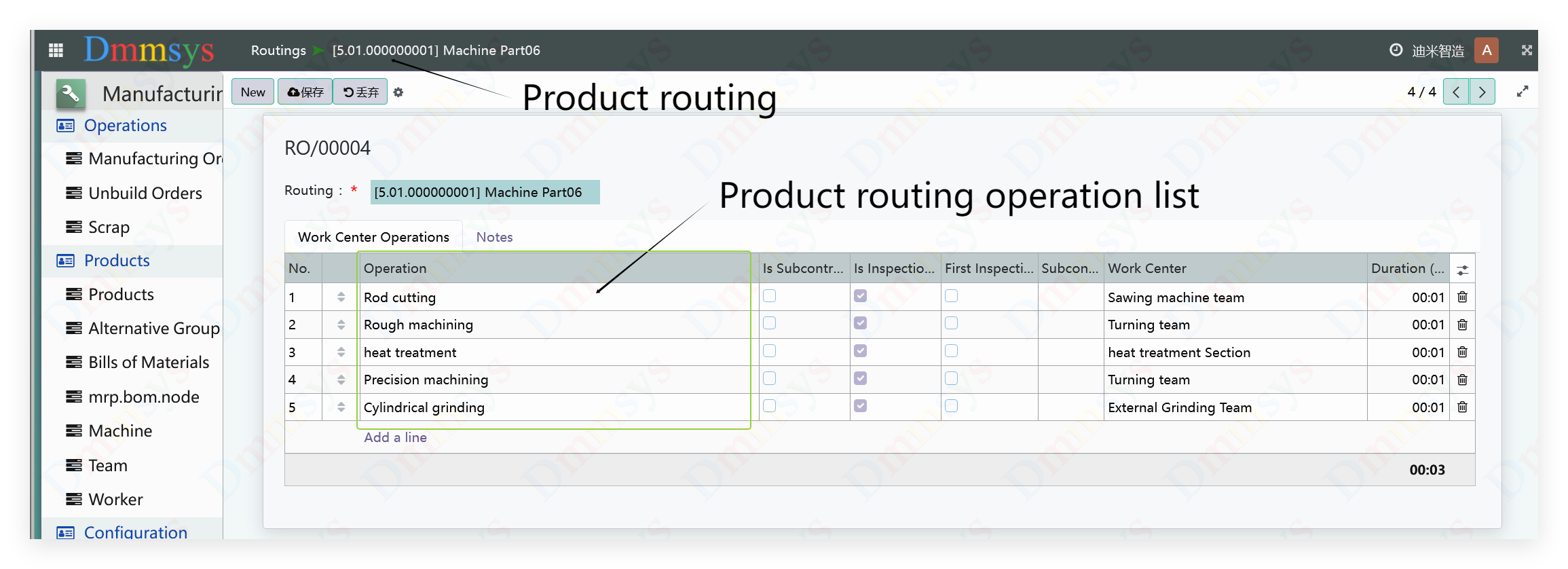

Mrp Routing Instance

For each product category that has enabled the process route template, an instantiated process route containing the template's general settings will be automatically generated.

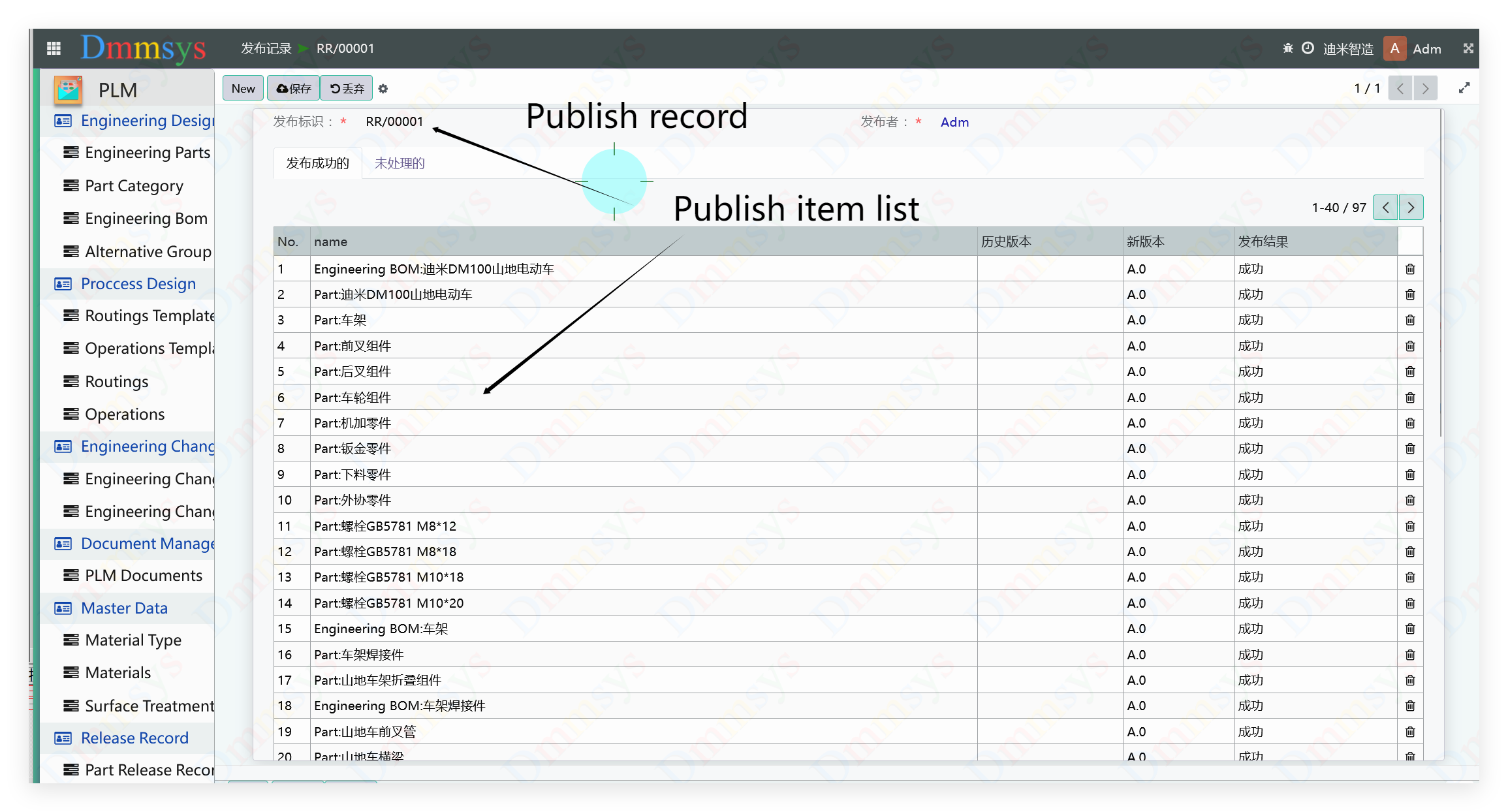

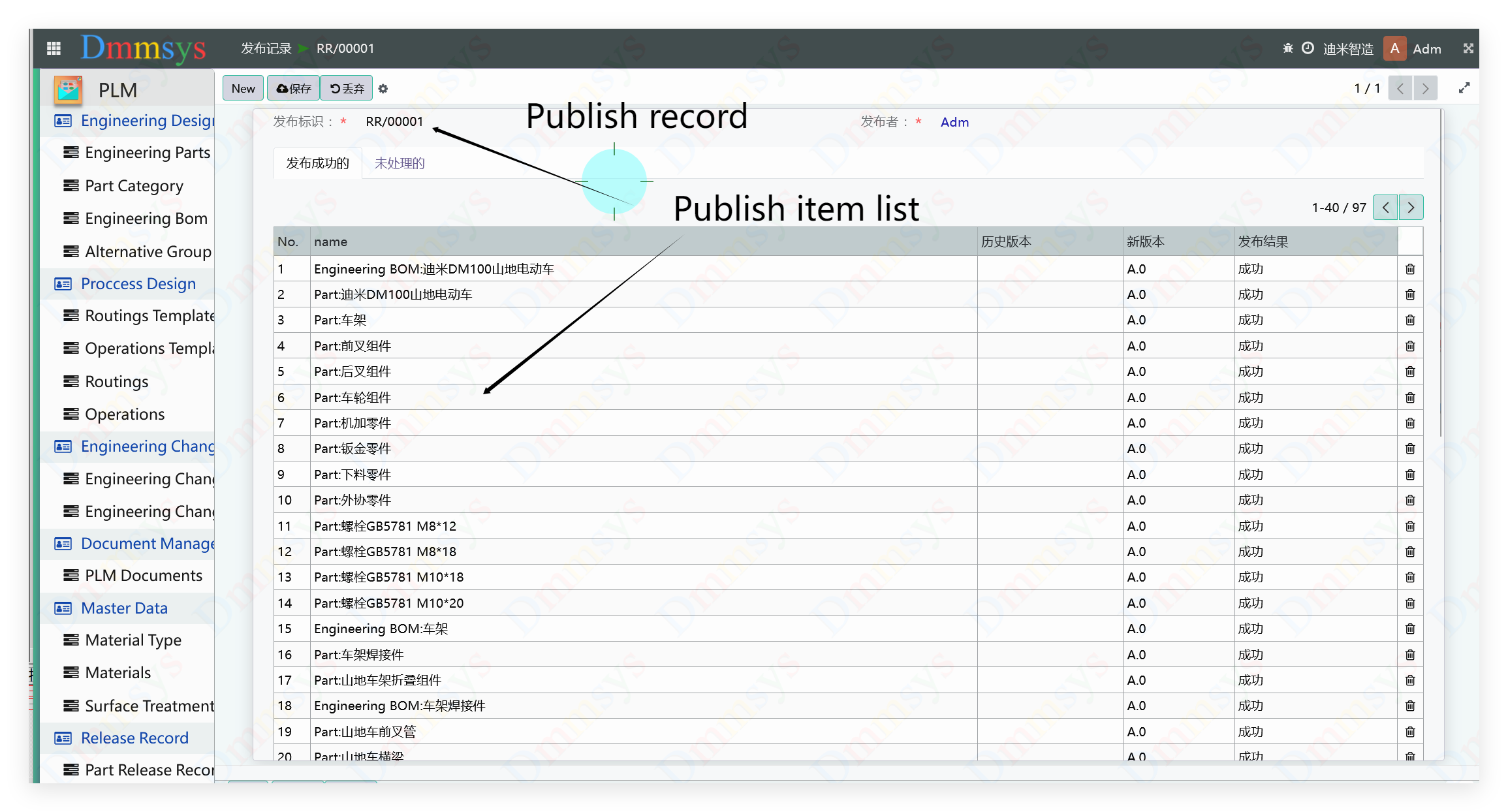

Publish Management

The system synchronizes and converts PLM system engineering BOM and engineering component data to ERP system manufacturing BOM and products through the release button.

Engineering Change Management

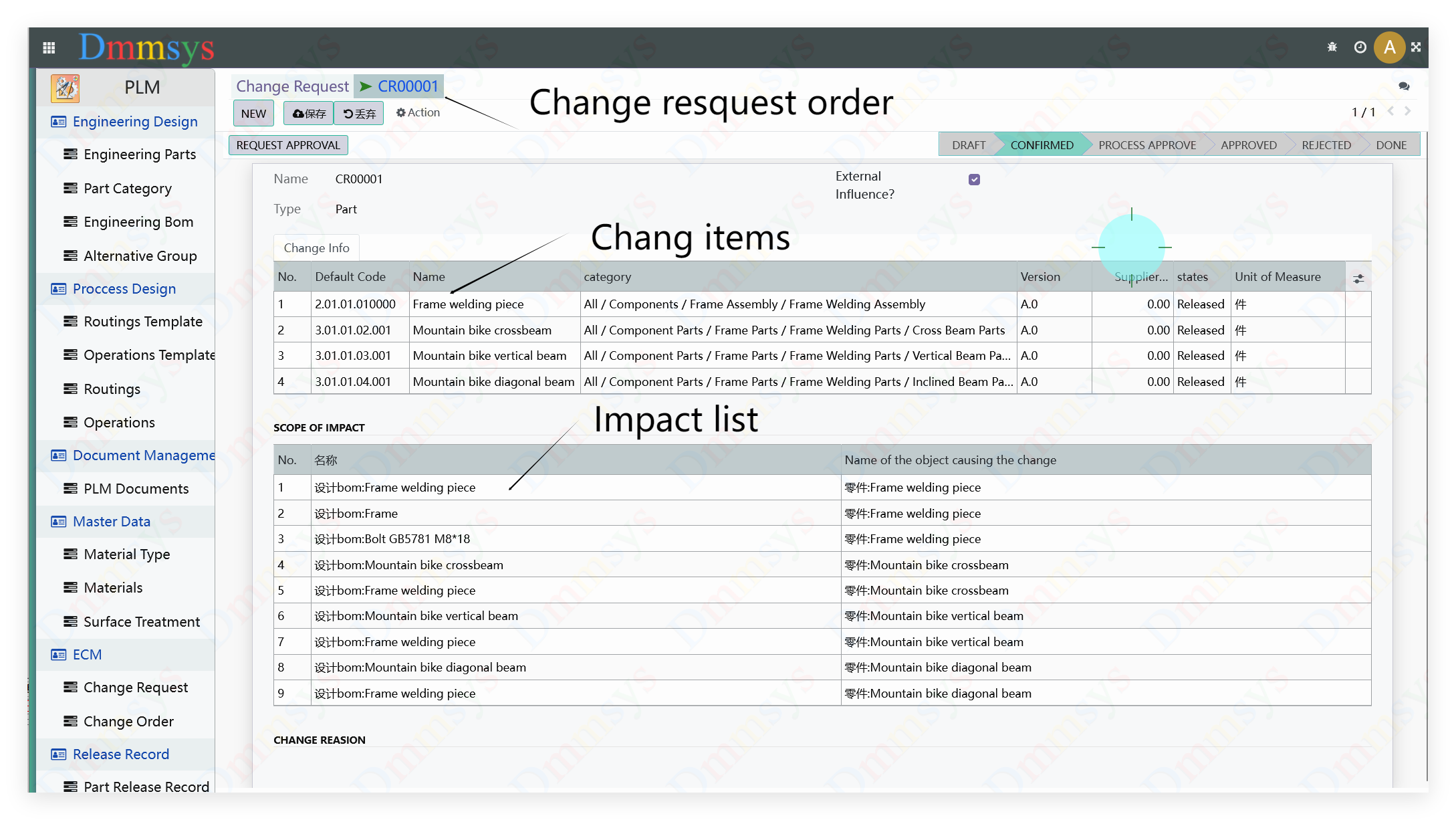

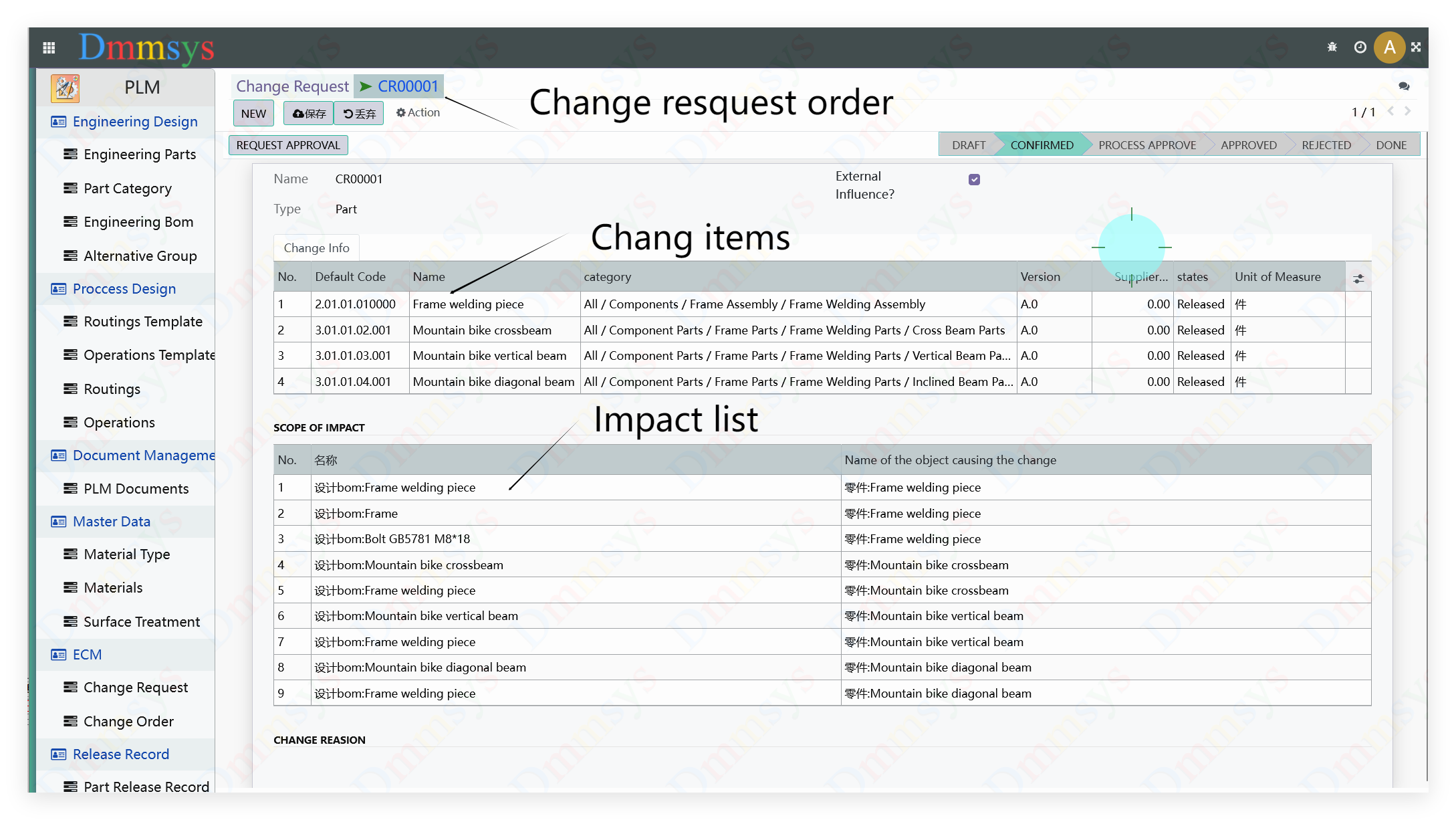

Referring to the Windchill system, we have implemented a simple change management function to manage the process from change request to creating change orders after the change request is approved.Engineering Change Request

The change request records the changed parts or BOM, and the change of parts will cause changes in the relevant engineering BOM.

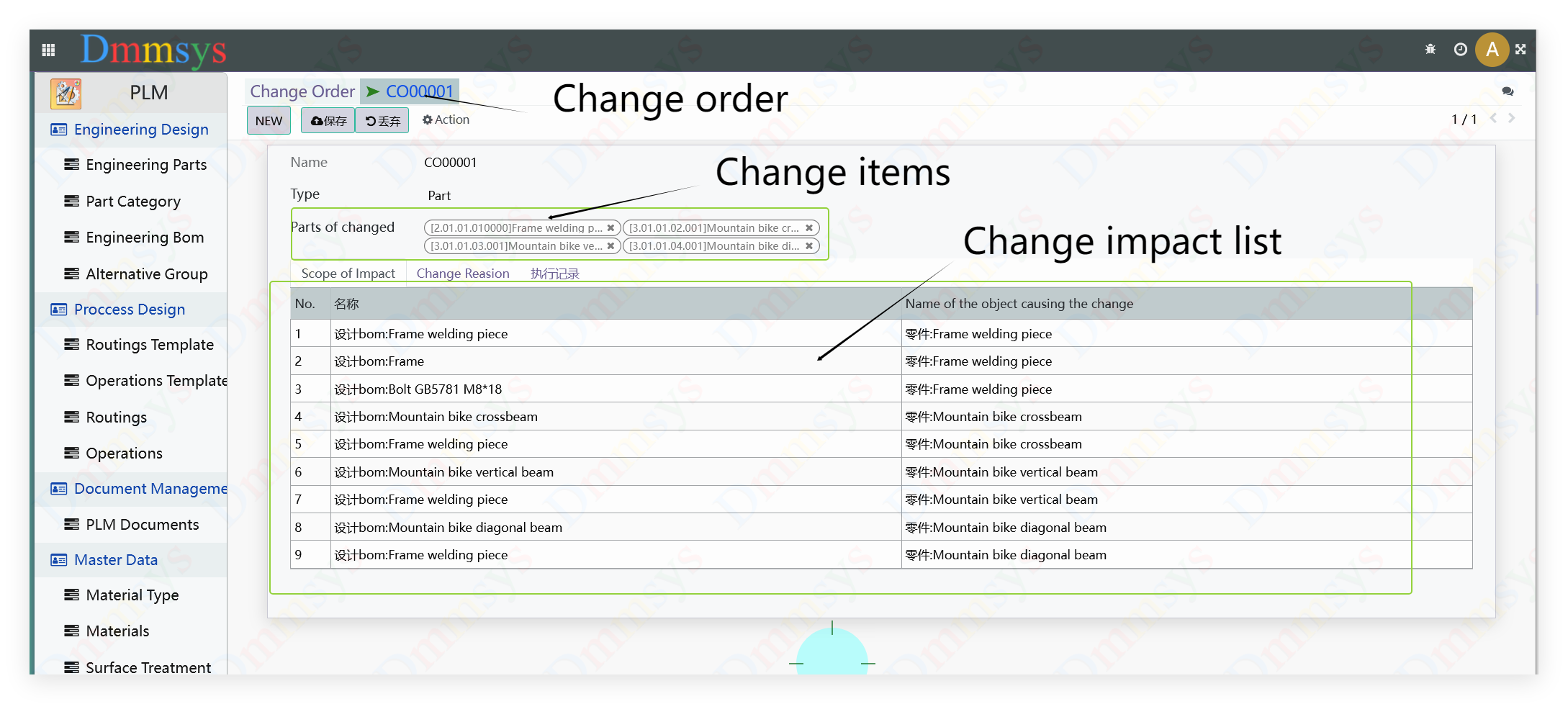

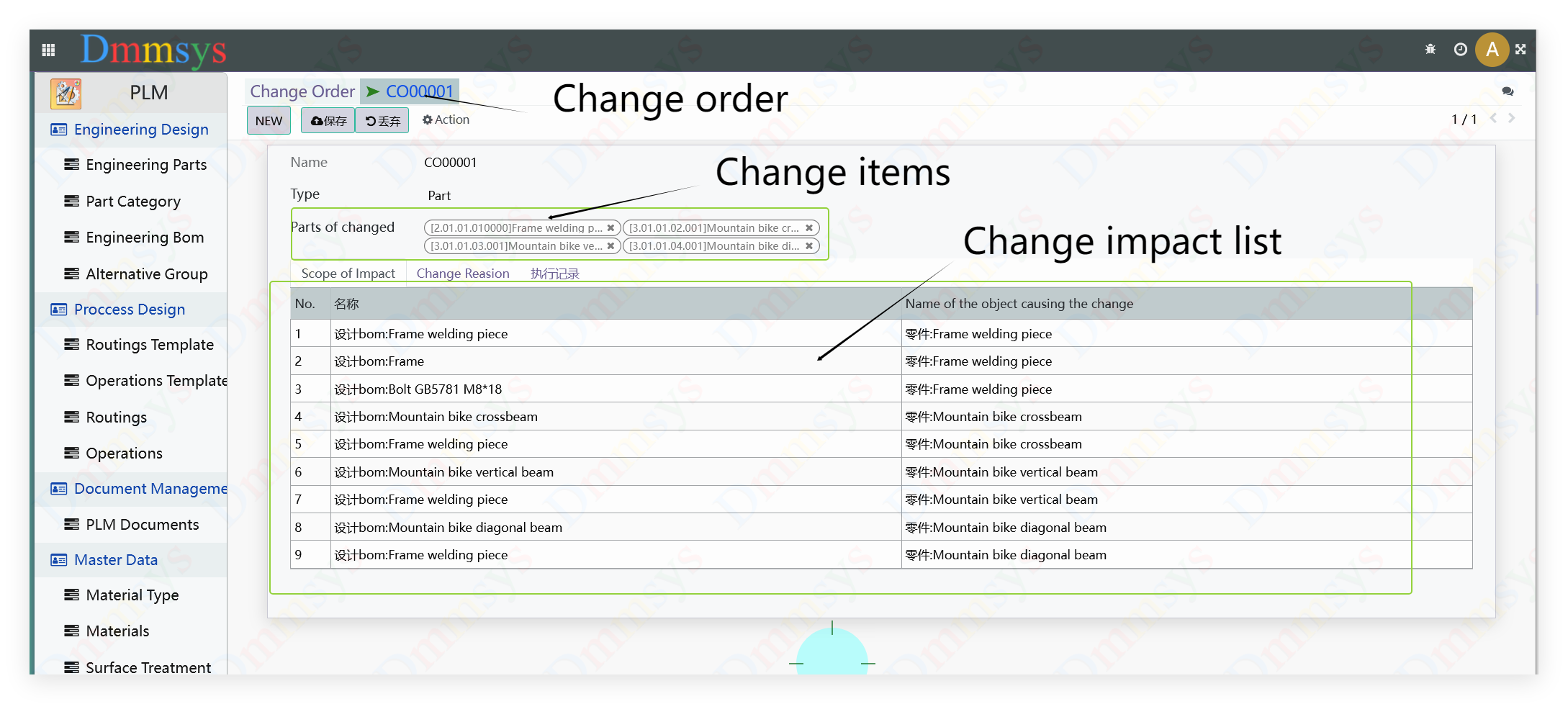

Engineering Change Order

After completing the approval process for the change request form, a change order will be automatically generated.

Access Control

Business objects in publishing status cannot be checked out for editing. Only after initiating a change request for the relevant business objects through the change management process and obtaining approval, can they be checked out for editing again.

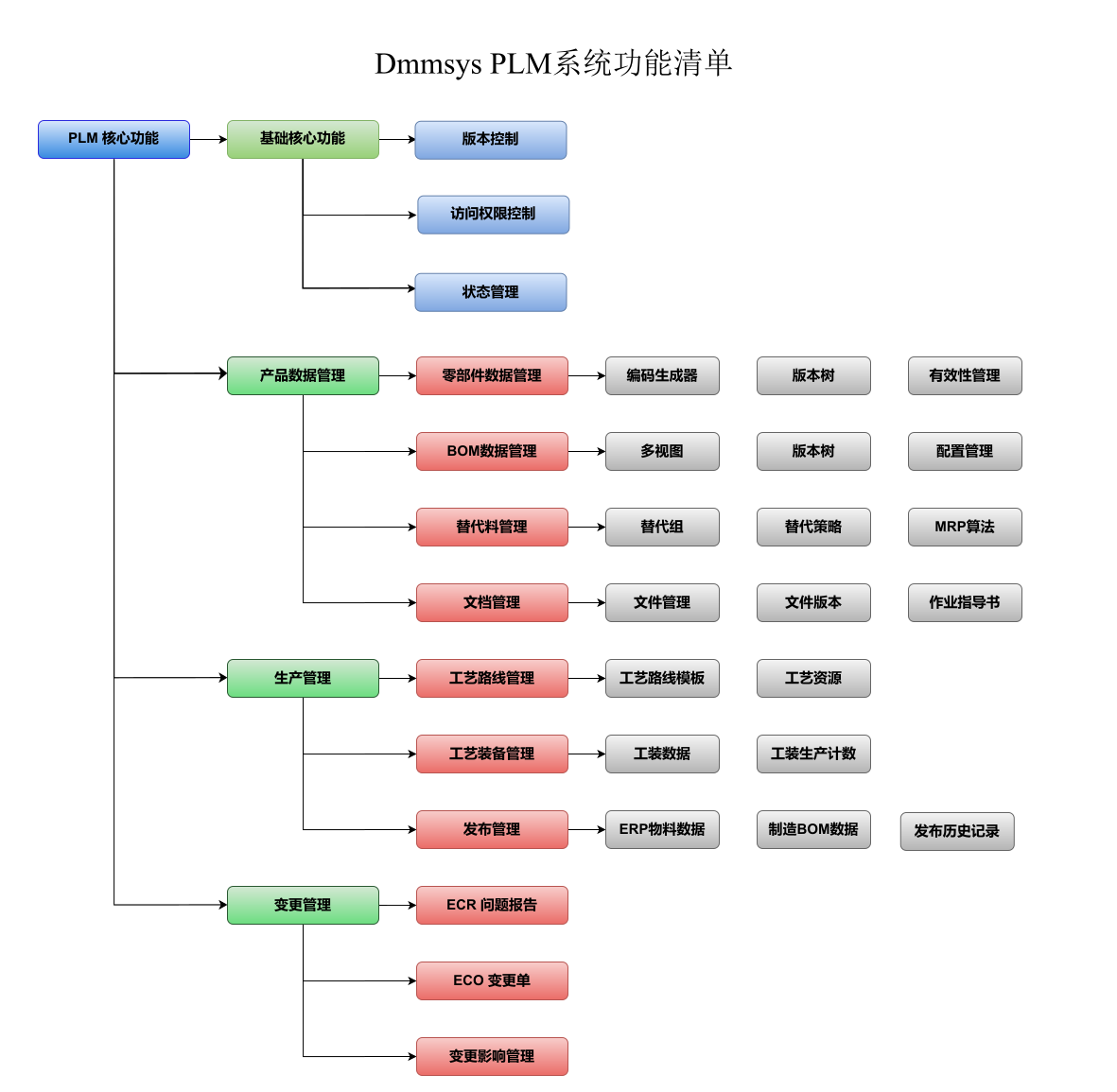

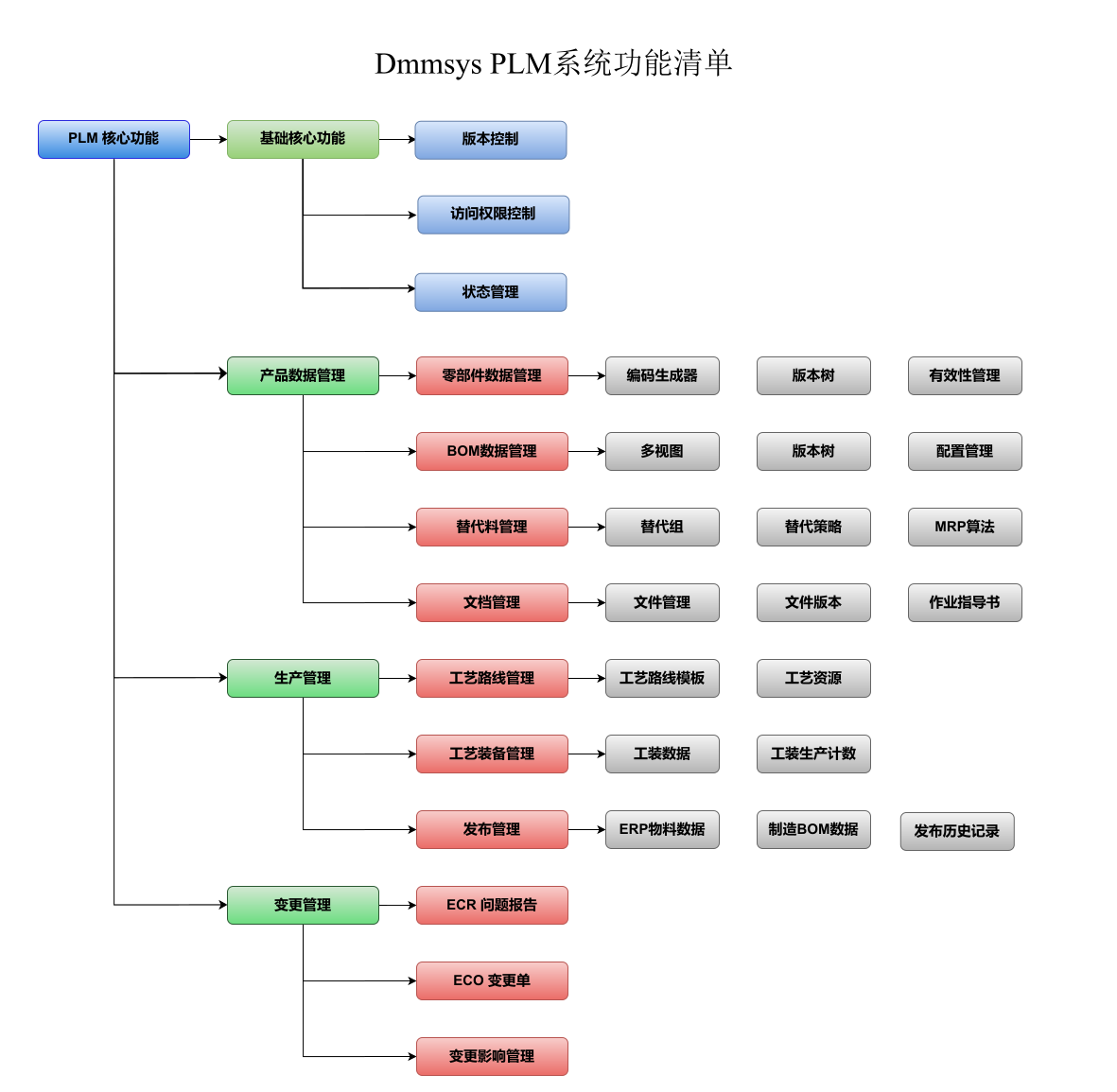

模块功能列表

DmmsysPLM系统参照Windchill系统的功能规划和实现机制, 实现了底层全局的访问控制权限管理、业务对象的状态管理以及统一的版本管理机的功能。基础核心功能

DmmsysPLM系统参照Windchill系统的功能规划和实现机制基于Odoo系统进行了开发和实现。

统一的版本管理

底层版本管理机制实现了对所有产品开发业务对象的版本控制。 版本分为大版本和小版本。设计师每次签入和签出时都会生成小版本,每次正式发布时都会产生大版本。

统一的访问权限控制

所有关键的产品研发业务对象,如零部件,图文档,工程bom,都有统一的签入签出访问控制机制, 通过对象签出时的只读权限控制,实现研发过程中的协同工作。

统一的状态管理

所有研发对象都有统一的状态管理机制,通过研发过程中不同的作业动作,和相应的状态转换,实现基础的研发工作流程控制。

产品数据管理

PLM系统最初就源自PDM系统,产品数据管理PLM系统最核心的功能部分。零部件数据管理

零部件管理包括产品零部件的自动编号,零部件的版本控制,状态控制和签入签出的访问控制等基础功能。

BOM 数据管理

BOM是核心制造BOM的数据源, 这不仅决定了组件制造的层次依赖关系, 而且决定了各级材料的标准定额。

BOM 结构树

产品结构树功能与这种自上而下的研发过程完美匹配, 并且可以在一个页面上完成创建产品结构树的整个过程。

图文档管理

在OCA基础的dms文档管理模块之上,我们针对PLM图文档管理, 进行了一系列的功能扩展,来实现完整的PLM系统的图文档管理功能。m

生产管理

DmmsysPLM通过按类别分类的预定义工艺路线模板实现了产品工艺路线实例的快速创建。

制造工艺路线模板

工艺路线模板定义一类零部件在实际业务中加工的通用的工序步骤。

制造工艺路线实例

每一个分类启用了工艺路线模板的产品,都会自动生成一个包含模板通用设置的实例化的工艺路线。

发布管理

系统通过发布按钮,实现PLM系统工程BOM和工程零部件数据,向ERP系统的制造BOM和产品进行同步和转换的过程。

工程变更管理

管理从变更申请到变更申请通过后创建变更单的过程。变更申请单

变更申请记录变更的零部件或者bom,零部件变更会引起相关工程BOM的变更。

s变更单

变更申请单走完审批流程后,自动生成变更单。

访问权限控制

发布状态的业务对象不能签出进行编辑,只有通过变更管理的流程,对相关业务对象发起变更申请并通过后,才能进行再次的签出编辑。

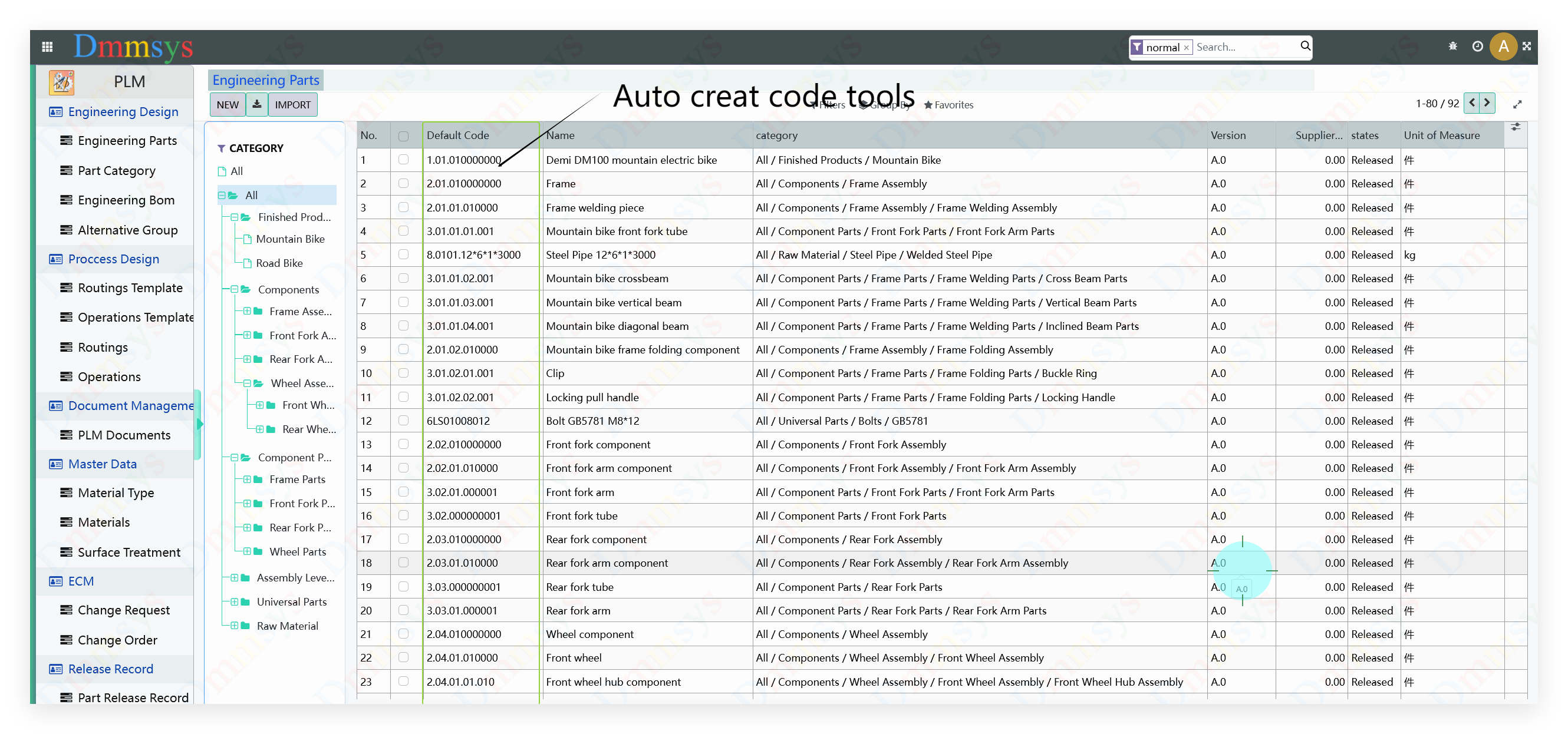

System Function Screenshot

No! Since the Odoo front-end has major changes in each version, all front-end modules do not support cross-version use.

According to Odoo's official policy, starting from version 13, each new version of the module needs to be purchased separately, if you need to upgrade the Odoo version, you need to repurchase our corresponding version of the module .

Yes, the module works well with Odoo Enterprise as well as Community. .

Yes, You can contact us through any way listed in the first part of the module description,such as email, skeype.

Suggested Products

Dmmsys Product LifeCycle Management

Product development management is the starting point of the business chain in the manufacturing industry.

Without accurate product and BOM (Bill of Materials) basic data provided by the product development process,

the ERP (Enterprise Resource Planning) system is likely to encounter issues during use due to confusion in product basic data,

which in turn may affect the normal operation of the business.

Different from traditional PLM systems, the primary objective of developing the Dmmsys PLM system is to achieve integrated digital management for the manufacturing industry, providing a unique source of product and BOM data for subsequent production and manufacturing organization processes. Secondly, it manages the individual achievements of engineers in research and development, design models, and 2D engineering drawings. From the perspective of overall manufacturing management, the content managed by the PLM system includes not only the 3D models and 2D engineering drawings delivered by engineers, but more importantly, the parameter data about products (materials) behind these deliverables, such as material, dimensions, tolerances, and design BOM data.

Dmmsys 产品生命周期管理系统

产品开发管理是制造业业务链的起点。如果产品开发过程中没有提供准确的产品和BOM(物料清单)基础数据,

ERP(企业资源计划)系统在使用过程中可能会因产品基础数据混乱而遇到问题,进而影响业务的正常运行。.

与传统的PLM系统不同,开发Dmmsys PLM系统的主要目标是实现制造业的集成数字化管理,为后续的生产和制造组织过程提供独特的产品和BOM数据来源。 其次,它管理工程师在研发、设计模型和二维工程图纸方面的个人成就。从整体制造管理的角度来看, PLM系统管理的内容不仅包括工程师交付的3D模型和2D工程图纸,更重要的是, 这些交付成果背后的产品(材料)参数数据,如材料、尺寸、公差和设计BOM数据。

Key Feature

The DmmsysPLM system follows the functional planning and implementation mechanism of the Windchill system, Implemented the functions of global access control permission management at the bottom level, state management of business objects, and unified version management machine.Basic core functions

The DmmsysPLM system was developed and implemented based on the Odoo system, following the functional planning and implementation mechanism of the Windchill system.Unified Version Management

The underlying version management mechanism implements version control for all product development business objects. Versions are divided into large and small versions. Designers generate small versions every time they check in and out, and generate large versions every time they officially release.

Unified Access Control

All key product development business objects, such as components, drawings, documents, and engineering BOMs, have a unified check-in and check-out access control mechanism. The underlying version management mechanism implements version control for all product development business objects. Versions are divided into large and small versions. Designers generate small versions every time they check in and out, and generate large versions every time they officially release.

Unified State Management

All R&D objects have a unified state management mechanism, which achieves basic R&D workflow control through different operational actions and corresponding state transitions during the R&D process..

Product Data Management

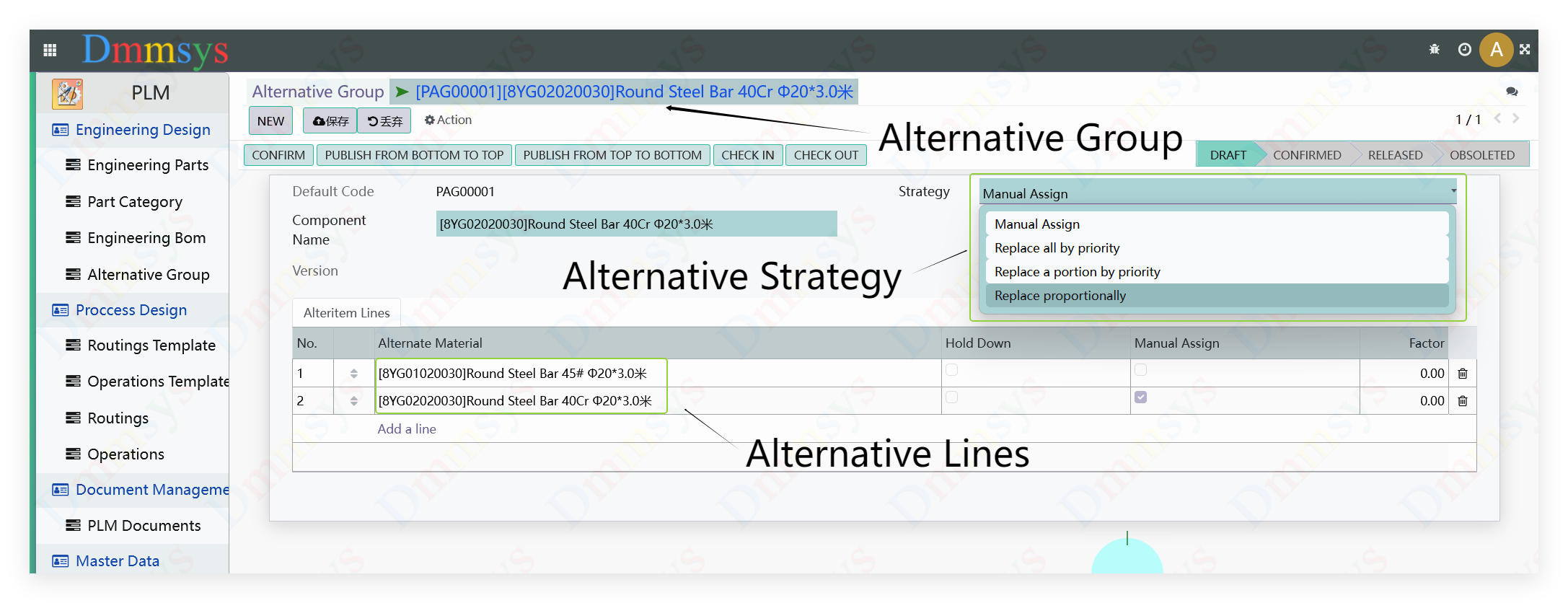

The PLM system originated from the PDM system, so product data management is the most core functional part of all PLM systems.Component Data Management

Component management includes basic functions such as automatic numbering of product components, version control of components, status control, and access control for check-in and check-out.

BOM Data Management

BOM is the data source of core manufacturing BOM, which not only determines the hierarchical dependency relationship of component manufacturing, but also determines the standard quota of each level of material.

BOM Structure Tree

The product structure tree function perfectly matches this top-down R&D process, and the entire process of creating the product structure tree can be completed on one page.

Drawing Document Management

On top of the DMS document management module based on OCA, we have carried out a series of functional extensions for PLM drawing document management to achieve the complete drawing document management function of the PLM system

Production Management

DmmsysPLM achieves rapid creation of process route instances through pre-defined process route templates classified by category.Mrp Routing Template

The process route template defines the general process steps for processing a type of component in actual business operations.

Mrp Routing Instance

For each product category that has enabled the process route template, an instantiated process route containing the template's general settings will be automatically generated.

Publish Management

The system synchronizes and converts PLM system engineering BOM and engineering component data to ERP system manufacturing BOM and products through the release button.

Engineering Change Management

Referring to the Windchill system, we have implemented a simple change management function to manage the process from change request to creating change orders after the change request is approved.Engineering Change Request

The change request records the changed parts or BOM, and the change of parts will cause changes in the relevant engineering BOM.

Engineering Change Order

After completing the approval process for the change request form, a change order will be automatically generated.

Access Control

Business objects in publishing status cannot be checked out for editing. Only after initiating a change request for the relevant business objects through the change management process and obtaining approval, can they be checked out for editing again.

模块功能列表

DmmsysPLM系统参照Windchill系统的功能规划和实现机制, 实现了底层全局的访问控制权限管理、业务对象的状态管理以及统一的版本管理机的功能。基础核心功能

DmmsysPLM系统参照Windchill系统的功能规划和实现机制基于Odoo系统进行了开发和实现。

统一的版本管理

底层版本管理机制实现了对所有产品开发业务对象的版本控制。 版本分为大版本和小版本。设计师每次签入和签出时都会生成小版本,每次正式发布时都会产生大版本。

统一的访问权限控制

所有关键的产品研发业务对象,如零部件,图文档,工程bom,都有统一的签入签出访问控制机制, 通过对象签出时的只读权限控制,实现研发过程中的协同工作。

统一的状态管理

所有研发对象都有统一的状态管理机制,通过研发过程中不同的作业动作,和相应的状态转换,实现基础的研发工作流程控制。

产品数据管理

PLM系统最初就源自PDM系统,产品数据管理PLM系统最核心的功能部分。零部件数据管理

零部件管理包括产品零部件的自动编号,零部件的版本控制,状态控制和签入签出的访问控制等基础功能。

BOM 数据管理

BOM是核心制造BOM的数据源, 这不仅决定了组件制造的层次依赖关系, 而且决定了各级材料的标准定额。

BOM 结构树

产品结构树功能与这种自上而下的研发过程完美匹配, 并且可以在一个页面上完成创建产品结构树的整个过程。

图文档管理

在OCA基础的dms文档管理模块之上,我们针对PLM图文档管理, 进行了一系列的功能扩展,来实现完整的PLM系统的图文档管理功能。m

生产管理

DmmsysPLM通过按类别分类的预定义工艺路线模板实现了产品工艺路线实例的快速创建。

制造工艺路线模板

工艺路线模板定义一类零部件在实际业务中加工的通用的工序步骤。

制造工艺路线实例

每一个分类启用了工艺路线模板的产品,都会自动生成一个包含模板通用设置的实例化的工艺路线。

发布管理

系统通过发布按钮,实现PLM系统工程BOM和工程零部件数据,向ERP系统的制造BOM和产品进行同步和转换的过程。

工程变更管理

管理从变更申请到变更申请通过后创建变更单的过程。变更申请单

变更申请记录变更的零部件或者bom,零部件变更会引起相关工程BOM的变更。

s变更单

变更申请单走完审批流程后,自动生成变更单。

访问权限控制

发布状态的业务对象不能签出进行编辑,只有通过变更管理的流程,对相关业务对象发起变更申请并通过后,才能进行再次的签出编辑。

System Function Screenshot

No! Since the Odoo front-end has major changes in each version, all front-end modules do not support cross-version use.

According to Odoo's official policy, starting from version 13, each new version of the module needs to be purchased separately, if you need to upgrade the Odoo version, you need to repurchase our corresponding version of the module .

Yes, the module works well with Odoo Enterprise as well as Community. .

Yes, You can contact us through any way listed in the first part of the module description,such as email, skeype.